In modern manufacturing, speed and flexibility define competitiveness. Customers expect faster delivery, smaller order quantities and more customization; all without compromising quality. To meet these demands, manufacturers must eliminate wasted time in every process, starting with one of the most critical sources of inefficiency: changeovers.

What Is SMED?

Developed by Shigeo Shingo at Toyota, SMED is a systematic approach designed to reduce equipment setup and changeover times from hours to minutes. The goal isn’t necessarily to reach under 10 minutes, but rather to minimize downtime so that machines spend more time adding value, not waiting to start.

A traditional setup might involve stopping production, fetching tools, adjusting equipment, testing and inspecting until the next batch is ready. SMED transforms this entire process through standardization, preparation, and separation of tasks, allowing teams to achieve quick, consistent, and error-free changeovers.

Why Changeover Time Matters

Many factories operate with large batch sizes to “avoid” frequent changeovers. While it seems efficient, this approach often hides several forms of waste:

-

Excess inventory – tying up cash and storage space

-

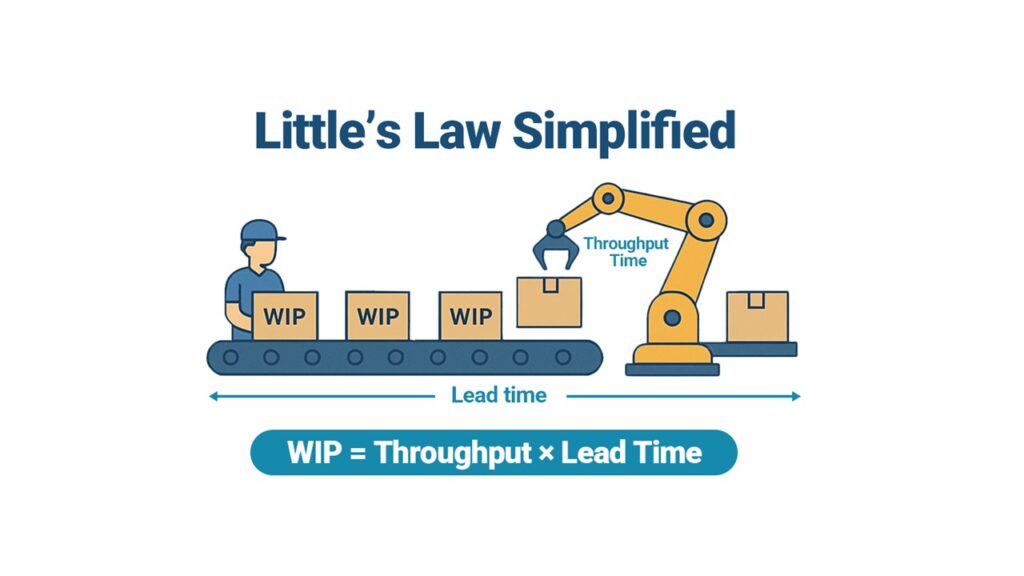

Long lead times – delaying responsiveness to customer demand

-

Overproduction – creating goods before they’re needed

-

Reduced flexibility – making it difficult to switch between product models or variations

By reducing setup time, organizations gain the ability to produce in smaller, more flexible batches, shorten lead times and respond to customer orders faster; without increasing costs. This shift is essential for companies aiming to move toward Lean and agile production systems.

The Core Principles of SMED

SMED is implemented in four main stages, each designed to progressively shorten setup time and increase efficiency:

-

Observe the current changeover process – Record the entire sequence in detail, noting each step and how long it takes.

-

Separate internal and external activities – Internal tasks can only be performed when the machine is stopped, while external tasks can be done while it’s running.

-

Convert internal to external activities – Shift as many tasks as possible to before or after the machine stops (e.g., pre-staging materials or tools).

-

Streamline and standardize all remaining steps – Use quick clamps, locating pins, color-coded setups, or checklists to simplify and speed up the process.

By repeatedly applying these principles, manufacturers often reduce changeover times by 50–90%, unlocking enormous productivity gains.

Real-World Results and Benefits

Implementing SMED provides a measurable impact across multiple performance areas:

-

Higher equipment utilization – Machines spend more time producing, not waiting.

-

Shorter lead times – Faster product changes lead to quicker delivery cycles.

-

Lower inventory levels – Enables smaller, just-in-time production batches.

-

Improved quality – Consistent setups reduce the likelihood of errors or defects.

-

Increased flexibility – Easier adaptation to demand fluctuations and new product introductions.

-

Enhanced team engagement – Operators become problem solvers, not just machine users.

In essence, SMED converts idle time into productive time, creating a direct link between operational speed and profitability.

Through hands-on programs like the TPS Training Programs, manufacturers can deepen their understanding of how Lean tools such as SMED integrate into a stable, high-performing production system. This alignment between method and mindset enables organizations to build more responsive, efficient and waste-free operations, where every process improvement contributes directly to long-term operational excellence.

Laying the Groundwork for Digital Transformation

Before adopting complex digital solutions, SPEED helps identify bottlenecks, visualize value streams and streamline workflows before the digital layer is applied.

Together, they build a strong operational backbone that supports sustainable digital transformation and measurable productivity gains.

Conclusion

In today’s manufacturing environment, success favors those who can change quickly without losing quality or control. SMED isn’t just about faster changeovers; it’s about building the operational flexibility, reliability and visibility needed to compete in a digital, demand-driven world.

By mastering these tools, manufacturers can create a production system that’s faster, leaner and future-ready capable of thriving in today’s dynamic market.