In every efficient manufacturing system, flow is the heartbeat of success. Whether you’re managing a production line, logistics, or service operations, understanding how work moves through your system is essential to achieving stability and speed.

That’s exactly where Little’s Law comes in, one of the simplest yet most powerful formulas in Lean management.

What is Little’s Law?

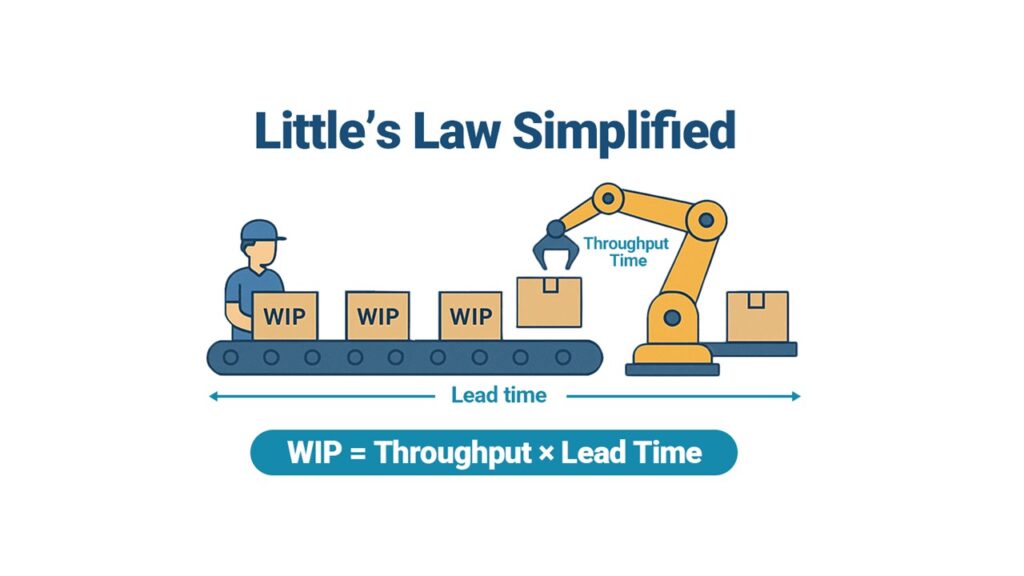

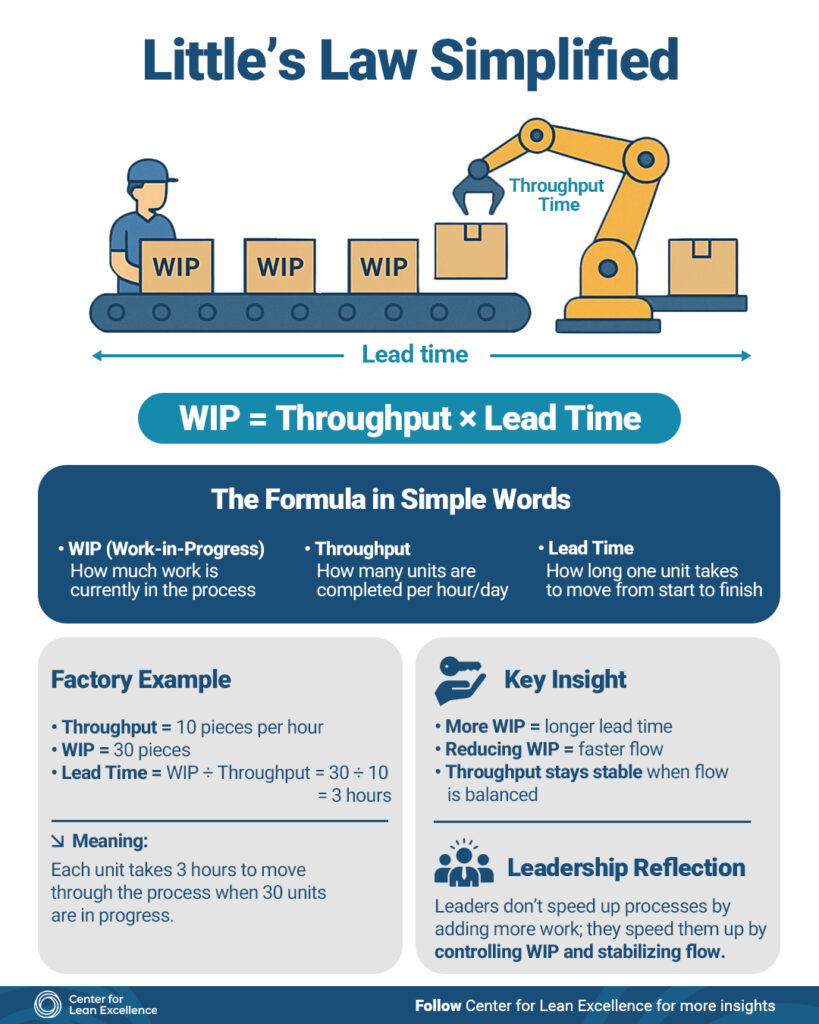

Little’s Law connects three key elements of any process:

WIP (Work in Progress) = Throughput × Lead Time

- WIP (Work-in-Progress): How much work is currently being processed.

- Throughput: How many units are completed per hour or per day.

- Lead Time: How long it takes for one unit to move from start to finish.

This law gives leaders a clear and measurable way to see how changes in one area, like increasing WIP or improving throughput, directly affect the overall performance of the system.

Factory Example

Let’s break it down with a simple example:

- Throughput: 10 pieces per hour

- WIP: 30 pieces

Using the formula:

Lead Time = WIP ÷ Throughput = 30 ÷ 10 = 3 hours

That means each unit takes 3 hours to move through the process when 30 units are in progress.

Key Insight

- More WIP → Longer lead time

- Reducing WIP → Faster flow

- Throughput remains stable when flow is balanced

In other words, adding more work doesn’t make your process faster, it actually slows things down. The secret lies in balancing flow, not overloading it.

Leadership Reflection

Leaders often believe increasing workload will improve productivity. But true performance improvement happens by controlling WIP and stabilizing flow.

When WIP is optimized, throughput becomes predictable, lead time shortens, and customers receive faster, more consistent delivery, the foundation of Continuous Improvement and Lean Management.

Why It Matters for Continuous Improvement

In a Lean or Auto-Production System, stability is everything.

Little’s Law gives teams a practical framework to:

- Visualize the impact of excess WIP on delays

- Optimize flow before scaling up operations

- Create a predictable, efficient production rhythm

- Support continuous improvement initiatives with measurable data

Every Kaizen event, line balance study, or process redesign can benefit from understanding and applying Little’s Law.

Takeaway

Little’s Law isn’t just a formula, it’s a mindset.

It teaches us that improvement doesn’t come from pushing more work into the system, but from making workflow smoothly through it.

If your goal is to build a stable, high-performing Auto-Production System, start by managing WIP, measuring lead time, and balancing throughput, that’s where transformation begins.