How TEEP, OOE and OEE Expose the Real Performance of Your Factory? In Lean manufacturing, capacity is often misunderstood. Many factories believe they are running at full capacity, yet they continue to struggle with missed deliveries, excess overtime, and constant production firefighting. The root cause is rarely a lack of machines or manpower; it is a lack of accurate capacity measurement.

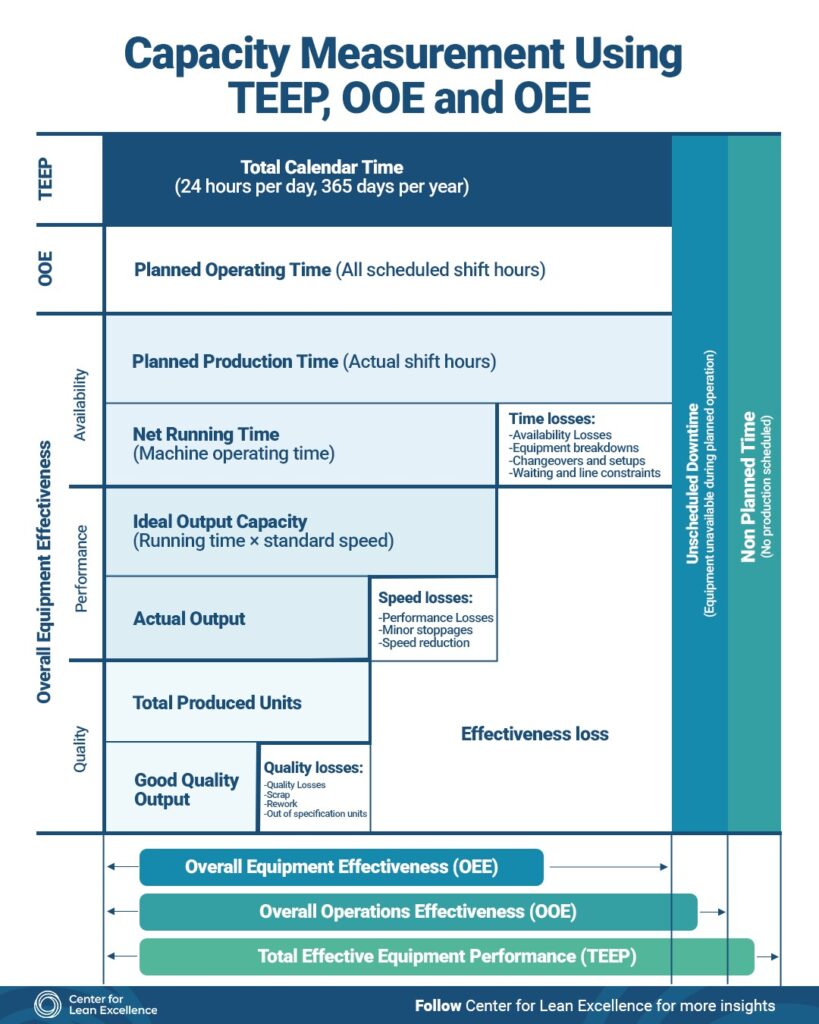

This is why OEE, OOE and TEEP are essential metrics in Lean management. Together, they provide a structured way to measure true manufacturing capacity, identify losses and support data-driven decision-making. The visual framework shown in the image above clearly illustrates how production time is reduced step by step due to availability, performance and quality losses; an insight that is central to Lean thinking.

Why Capacity Measurement Is Critical in Lean Management

Lean management focuses on maximizing value while eliminating waste. Without accurate capacity measurement, organizations make decisions based on assumptions rather than facts. This often leads to:

- Overinvestment in new equipment while existing assets are underutilized

- Poor production planning due to inflated capacity assumptions

- Ineffective continuous improvement initiatives

Accurate capacity metrics allow Lean leaders to stabilize operations, improve flow, and align production with customer demand. You cannot improve what you do not measure, and in Lean manufacturing, capacity is one of the most critical measurements.

Understanding Manufacturing Capacity Through Time-Based Metrics

As illustrated in the image, all capacity measurement starts with Total Calendar Time; 24 hours per day, 365 days per year. From this total time, multiple layers of losses reduce what is actually available for value-adding production.

Lean manufacturing emphasizes understanding these losses at a system level rather than blaming individual machines or operators. This is where OEE, OOE, and TEEP provide complementary insights.

OEE in Lean Manufacturing: Measuring Equipment Effectiveness

Overall Equipment Effectiveness (OEE) is a foundational metric in Lean manufacturing. It measures how effectively a machine performs during planned production time.

OEE is calculated using three components:

- Availability – losses from breakdowns, changeovers, setups, and waiting

- Performance – losses from speed reduction and minor stoppages

- Quality – losses from defects, scrap, and rework

From a Lean perspective, OEE highlights equipment-level waste and exposes instability on the shop floor. It is especially useful for identifying chronic losses that prevent standard work and flow.

However, OEE alone does not measure total manufacturing capacity. It only evaluates performance when production is already scheduled.

OOE: Linking Operations Planning to Lean Performance

Overall Operations Effectiveness (OOE) extends beyond OEE by considering planned operating time, including all scheduled shifts. OOE reveals losses related to:

- Inefficient shift patterns

- Labor and equipment mismatch

- Poor production scheduling

In Lean management systems, OOE connects operations management with equipment performance. It helps leaders understand whether capacity issues are caused by machines; or by how work is planned and managed.

OOE is particularly valuable in multi-shift or high-mix manufacturing environments where operational discipline directly impacts throughput.

TEEP: Revealing Hidden Manufacturing Capacity

Total Effective Equipment Performance (TEEP) provides the most comprehensive view of manufacturing capacity. It measures actual productive output against total calendar time, including non-scheduled hours.

TEEP answers a critical Lean question:

How much of our total available capacity are we actually converting into value?

By including non-planned production time, TEEP exposes strategic losses such as:

- Equipment not scheduled despite customer demand

- Conservative planning assumptions

- Organizational constraints limiting utilization

Many Lean transformations discover that significant capacity already exists; it is simply hidden by poor visibility and outdated planning logic.

Lean Insight: Capacity Losses Are Systemic

The image clearly shows how losses accumulate across availability, performance and quality. This reflects a core Lean principle:

capacity losses are systemic, not isolated.

Improving OEE without addressing operational and planning losses will not unlock full capacity. Lean organizations must use OEE, OOE, and TEEP together to gain a complete and accurate picture of performance.

Digital Lean Management and Real-Time Capacity Visibility

Modern Lean organizations increasingly embed these metrics into digital Lean operating systems. When OEE, OOE, and TEEP are tracked in real time:

- Bottlenecks become visible

- Improvement priorities become clear

- Management decisions become data-driven

Digital Lean systems transform capacity measurement from static reports into daily management routines, enabling faster problem-solving and sustainable continuous improvement.

Conclusion: Measure Capacity to Improve Flow

In Lean manufacturing, capacity is not what equipment could theoretically produce; it is what the system actually allows to flow.

By combining OEE for equipment effectiveness, OOE for operational efficiency and TEEP for total capacity utilization, Lean leaders gain the insight needed to improve flow, reduce cost and deliver reliably to customers.

That is the true power of capacity measurement in Lean management.