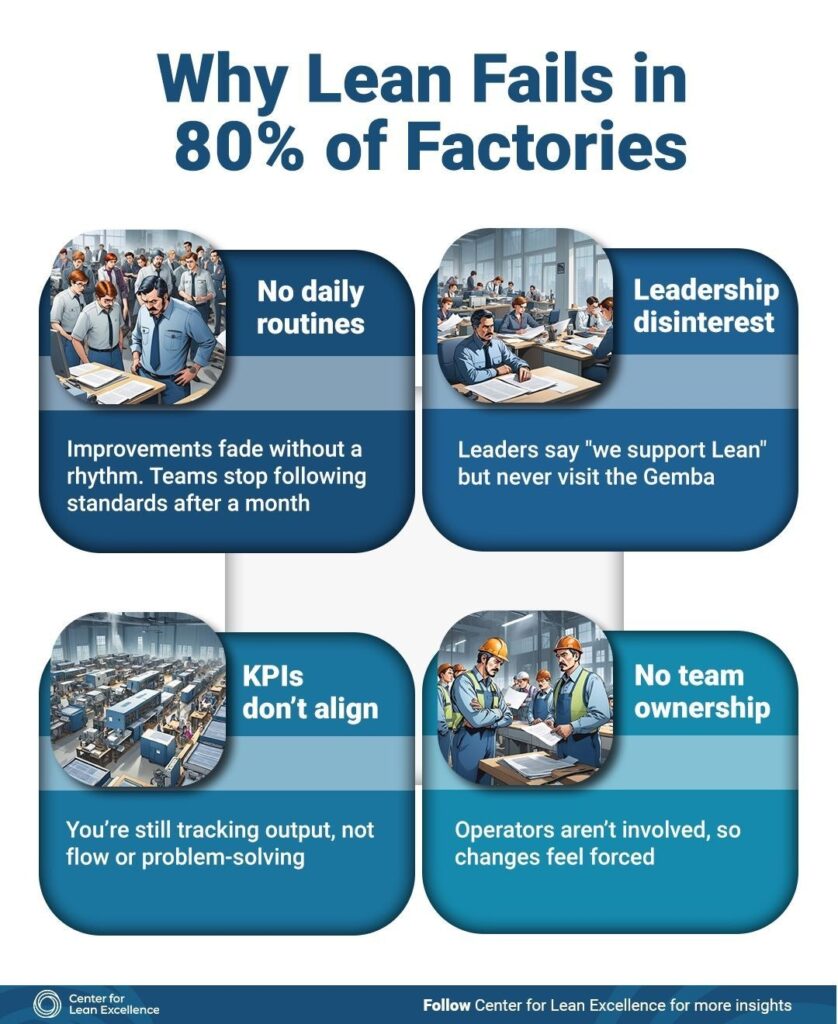

Lean has been discussed, taught, and implemented in manufacturing for decades. Why Lean Fails in 80% of Factories? Many organizations invest heavily in Lean training, hire consultants, run kaizen events, and roll out improvement projects. Yet despite all this effort, a common and uncomfortable reality remains: Lean initiatives fail or slowly fade in nearly 80% of factories.

This failure is rarely due to a lack of effort or intent. Most people genuinely want to improve their work. Operators want fewer problems, supervisors want smoother operations, and leaders want better performance. Lean does not fail because people do not care. It fails because the foundation is not built into daily work.

Below are the most common reasons we continue to see Lean break down on the factory floor.

1. No Daily Improvement Routines

One of the most overlooked elements of Lean is routine. Many factories start strong running workshops, implementing visual boards, and standardizing processes. But without daily routines, improvements quickly lose momentum.

Lean is not sustained by occasional projects; it is sustained by daily behaviors. When teams do not review performance daily, identify problems, and take small corrective actions, improvements slowly erode. Within weeks or months, people revert to familiar habits because those habits are reinforced every day. Daily management routines, such as shift start meetings, standard work checks, and problem escalation create a rhythm that keeps Lean alive. Without this rhythm, Lean becomes something people “did once” instead of something they do every day.

2. Leadership Disinterest at the Gemba

Another major reason Lean fails is the gap between leadership intent and leadership behavior.

Many leaders say they support Lean. They approve budgets, attend kick-off meetings, and talk about continuous improvement in presentations. But Lean lives on the Gemba where the work actually happens. When leaders rarely visit the shop floor, ask superficial questions, or focus only on output numbers, teams receive a clear message: Lean is not a real priority.

In successful Lean organizations, leaders regularly go to the Gemba. They observe processes, ask why problems occur, and support teams in solving them. Their presence is not about auditing or blaming; it is about learning and enabling improvement. When leadership behavior does not align with Lean principles, teams quickly disengage, and Lean becomes just another management initiative that will eventually pass.

3. KPIs That Are Not Aligned with Lean Thinking

What gets measured drives behavior. Unfortunately, many factories attempt to implement Lean while continuing to measure success almost exclusively through output, utilization, and short-term efficiency.

Lean focuses on flow, stability, quality, and learning. If KPIs reward pushing more volume regardless of problems, teams will bypass standards, hide issues, and firefight instead of improving. In such environments, Lean tools become cosmetic rather than transformational.

Aligned KPIs should encourage:

- Stable flow instead of maximum output

- Early problem detection instead of late correction

- Learning and improvement instead of heroics

When performance metrics contradict Lean principles, Lean has little chance of surviving.

4. No Real Team Ownership

Lean is often designed and driven by management or external experts, then handed down to operators. This creates resistance, even if unintentionally. Operators know their processes better than anyone else. When they are excluded from problem identification and solution design, improvements feel forced rather than owned. People may comply temporarily, but true engagement never develops.

Successful Lean systems treat operators as problem solvers, not just task executors. Teams are trained to see waste, raise issues, test improvements, and learn from results. Ownership transforms Lean from a “management system” into a people system. Without team ownership, Lean tools may be installed; but they will not be sustained.

5. Lean Fails When It Is Treated as a Project

The common thread across all these failures is this: Lean is treated as a project instead of a way of working.

Projects have start dates and end dates. Lean does not. Lean must be embedded into daily routines, leadership behaviors, performance systems, and team practices. It requires patience, consistency, and discipline; not just enthusiasm at the beginning. Factories that succeed with Lean focus less on tools and more on habits. They build systems that make the right behavior the easiest behavior, every day.

6. Building a Strong Lean Foundation

Lean success does not come from doing more workshops or installing more boards. It comes from:

- Establishing daily management routines

- Aligning leadership behavior with Lean principles

- Measuring what truly matters

- Involving teams early and continuously

When Lean becomes part of how work is done; not an add on it stops failing and starts delivering sustainable results.

Lean works.

But only when its foundation is built into daily work.

Conclusion

In today’s factories, manual routines, disconnected KPIs, and delayed visibility make it difficult to sustain Lean behaviors at scale. This is where a Digital Lean Operating Systems becomes critical. By embedding daily management, real-time performance visibility, structured problem-solving, and leadership routines into digital workflows, Lean moves from intention to execution. Digital transformation is not about adding technology; it is about enabling Lean to be practiced consistently every day across the entire organization, with clear visibility and actionable analytics.