Future-Ready People

Future-Proof Processes

For a Sustainable Business Transformation

What We Do

Lean Transformation Solutions

Lean Training Programs

Digital Lean Systems

Our Lean Transformation Solutions

Our Lean Training Programs

In collaboration with

Toyota Production System Certification

Learn about core Toyota lean manufacturing techniques and their practical application.

Toyota Management System Certification

Learn about Toyota’s leadership and management style

Our Digital Lean System

Our Digital Lean Solution, featuring comprehensive virtual A3 project and Kaizen management modules, will help you simplify your lean management system better than ever before

Our Versatility

Our Prestigious Clients

Our Corporate Partners

Lean Toyota Production System Partner

TOYOTA ENGINEERING CORP JAPAN

Toyota Engineering Corporation (TEC) Japan, is the official body to impart knowledge on Toyota Production System (TPS). CLE is the partner-corporate member for TEC for Sri Lanka and the region. CLE has embarked on spreading true TPS knowledge for individuals and corporates along with globally recognized TPS certification.

Industry 4.0 Partner

XDOTO CONCEPTS SINGAPORE

XDoto Concepts stands at the forefront of innovation, seamlessly merging design thinking with technological prowess to craft bespoke solutions that transcend conventional boundaries. With a relentless commitment to user-centricity, they consistently redefine digital experiences, ensuring their clients stay ahead.

Providing customized knowledge and solutions that works!

What is Lean Management?

Lean management is a widely accepted method of achieving operational excellence that is founded on a philosophy of maximizing productivity while minimizing waste during manufacturing or service operations. This is accomplished via the use of proven “lean management” methodologies. It is a strategic approach to provide optimum value to the customer considering the customer’s perspective, while consuming the fewest resources and utilizing the talents of the people who do the work. In the late 1980s, American scholars researched the famous Toyota Production System which was developed by Toyota Motor Corporation Japan. They discovered that the revolutionary manufacturing methodologies that are used in Toyota could be beneficial for any industry and coined the term “Lean Management” to refer this. Since then thousands of businesses in various industries across the world have adopted lean management methodologies to create significant productivity improvements in profitability, capacity, quality and employee morale.

Testimonials

Featured Articles

Read about what we do and what you can achieve as organizations and individuals with the help of us.

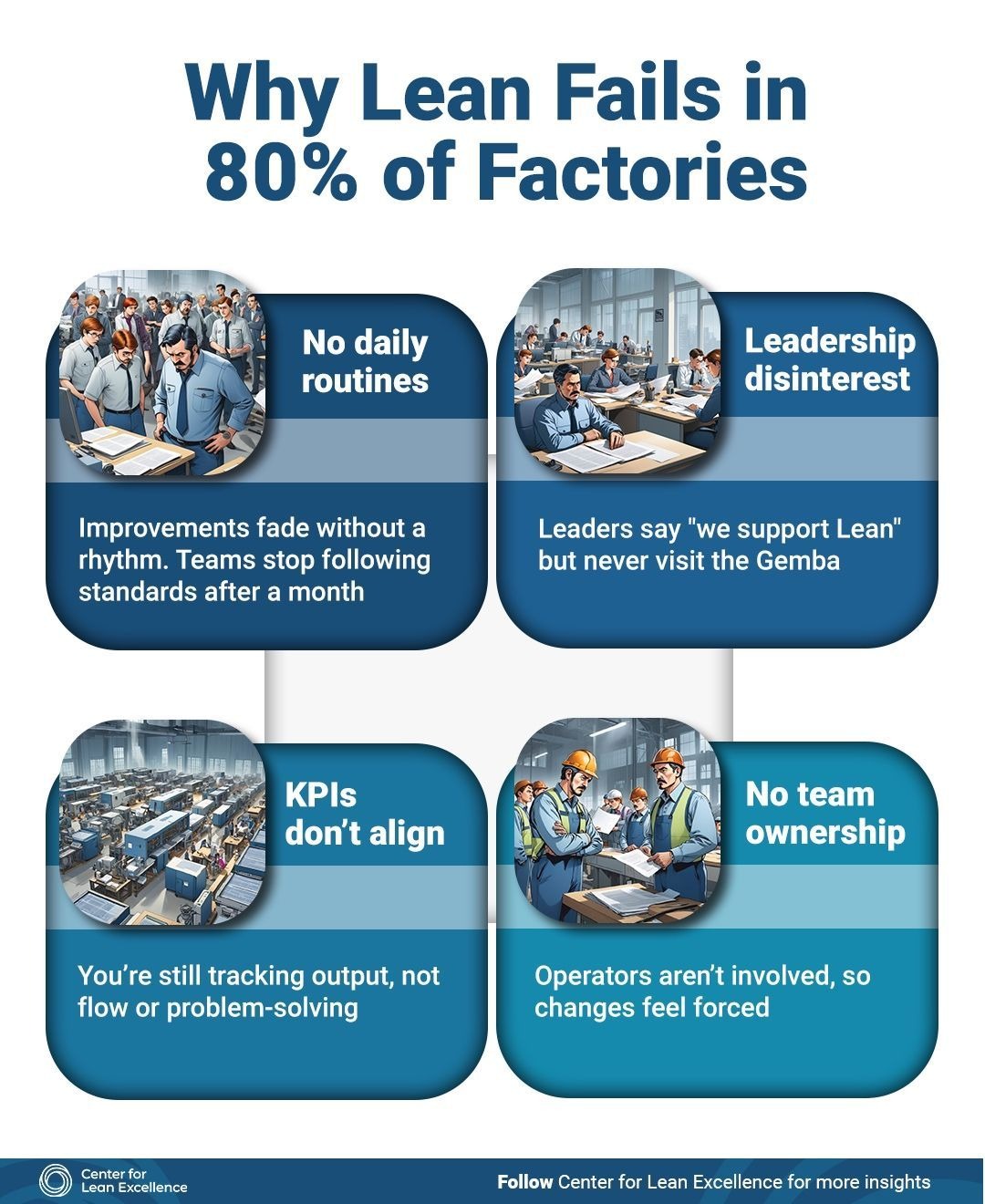

Lean has been discussed, taught, and implemented in manufacturing for decades. Why Lean Fails in 80% of Factories? Many organizations invest heavily …

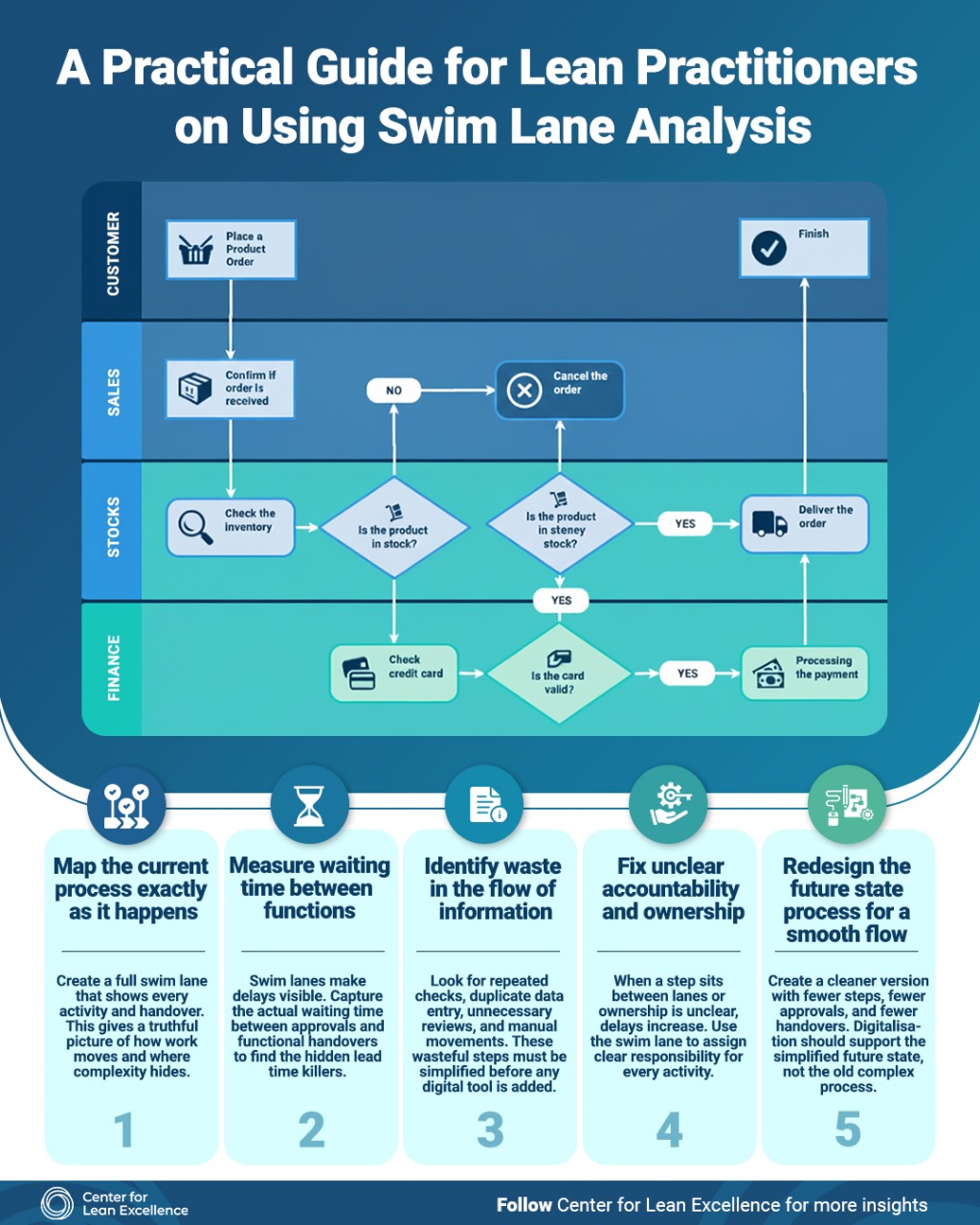

”How the Swim Lane Structure Reveals the True Workflow; Value of Swim Lane Analysis in Lean Practice.” In many organizations, leaders and …

How ‘Reducing Lead Time’ Transforms Factory Performance? In modern manufacturing, speed is not just about machines running faster; it’s about how smoothly …

Discover the Role of Lean Consultant in Digital Transformation and why Lean experts are essential for reducing waste, aligning processes and ensuring …

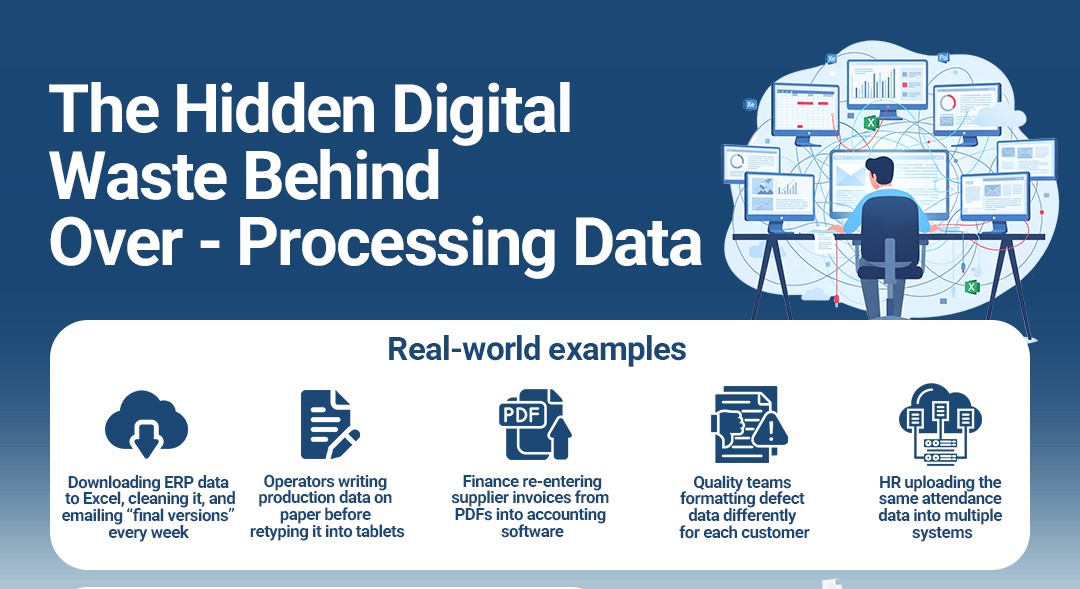

Why One Clean Process Matter More Than 100 Software? In the race toward “digital transformation,” many organizations unknowingly create more waste instead …

In every efficient manufacturing system, flow is the heartbeat of success. Whether you’re managing a production line, logistics, or service operations, understanding …

Send Us A Message

Contact Us

info@54.196.139.248

Phone

+65 8480 6350

Address

10, Anson Road, #31-10, International Plaza, Singapore. 079903