Diagnosis

Illuminate the Unseen, Shape Your Future!

Experience the power of our Factory Diagnosis solutions, meticulously designed to uncover hidden inefficiencies and steer your organization towards enhanced profitability. With our systematic diagnostic approach, we shine a light on the unseen, allowing leaders to refocus their efforts on shaping a prosperous future for their organization.

Only a mere 4% of an organization's issues are visible to top leadership.

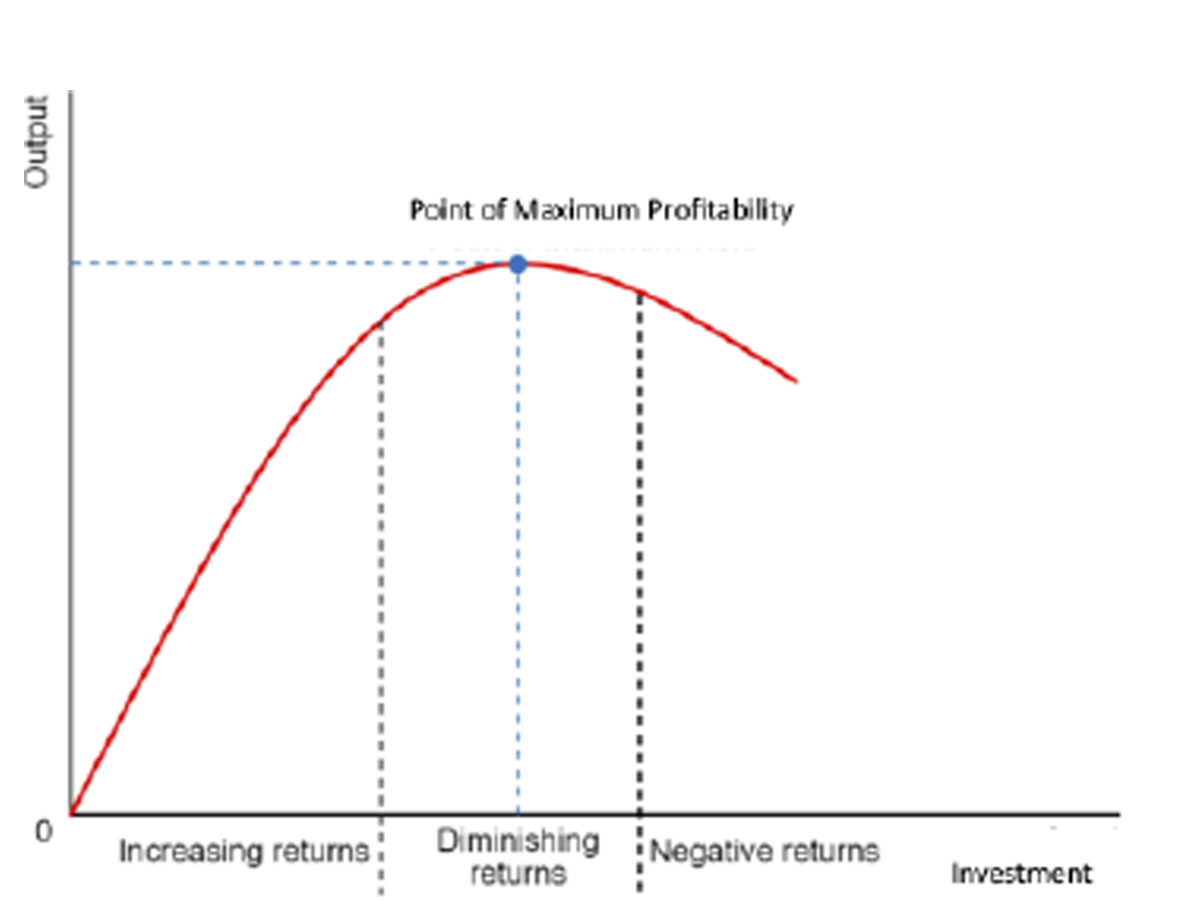

While symptoms such as declining profitability, escalating costs per hour, and diminished revenue per employee may be apparent, the underlying causes reside within the remaining 96%, unseen by leadership. Through a systematic diagnostic approach, we aim to uncover these hidden causes and address them promptly, allowing leaders to redirect their focus towards shaping the organization’s future. Factory Diagnosis is like a comprehensive health check for your operations, designed to unveil hidden issues and boost profitability.

Symptom 1

Increased Capex due to Expansion & Machinery Purchases

What are the causes?

Increased capital expenditure (Capex) often stems from hidden capacity, which can have various causes. The primary culprit is often process bottlenecks, which arise due to imbalances between processes. These imbalances may result from planning methods, process downtimes, changeover inefficiencies, uneven manpower distribution, or inadequate information flow. Identifying bottlenecks is achievable by observing work progress between processes. While CEOs may be aware of these factors, they may hesitate to unlock this potential promptly to accommodate growth. However, with a clear understanding of where and how losses occur, realizing this potential can be swift.

Hidden Capacity Diagnosis

Key methods:

Value Stream Mapping & Constraint Analysis

Estimated time:

2 weeks

Two of the most valuable tools in the lean toolbox are utilized to accurately determine hidden capacity within the business. A comprehensive value stream analysis will be conducted to assess takt time, cycle times, inventory levels, information flow status, process capability, and personnel distribution. All process inefficiencies will be identified through observations, interviews, and past data analysis.

Outcomes:

Symptom 2

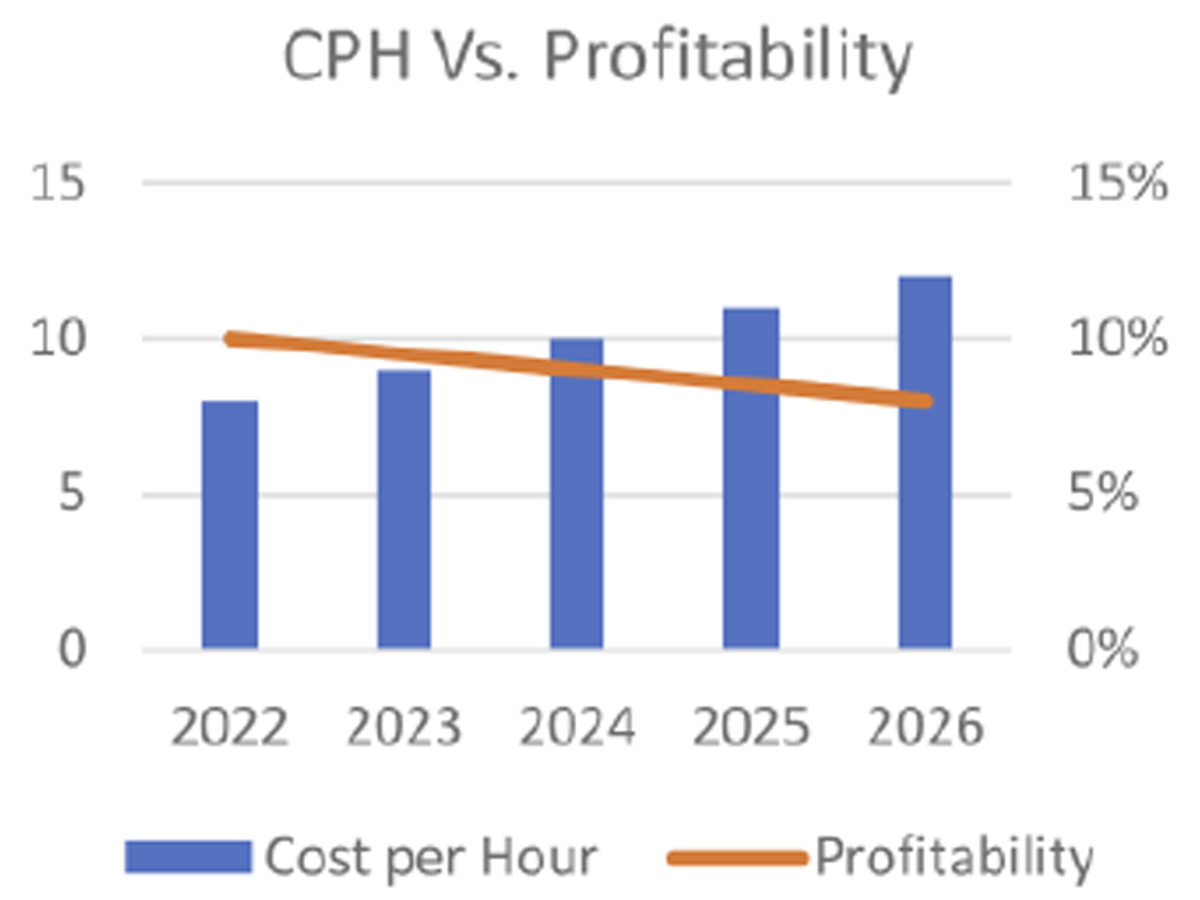

Increased Production Cost Per Hour (CPH)

What are the causes?

Defects, recalls, customer complaints, inventory mismanagement, overtime hours, demurrage, airfreight, short-term interest, spare parts, material wastage, electricity, utility bills, transportation, and temporary workers can incur significant losses. Simply meeting budgeted defect rates or losses should not suffice, as preventable downtime or defects should be intolerable for any business.

Many of these issues have interconnected causes, where one factor may lead to multiple losses across various areas. For example, defects can result in manpower hours, wasted materials, airfreight expenses, and utility costs. This cumulative waste drives up the cost per hour (CPH) and erodes company profits.

Loss Cost Diagnosis

Key methods:

16 Losses Overall Equipment Effectiveness (OEE) First Time Through (FTT) Delivery In Full On Time (DIFOT)

Estimated Duration:

4 weeks

A comprehensive diagnosis involves past data analysis, focused studies, and design of experiments. This study quantifies total losses within the company, segregating them by department and loss type. Additionally, potential financial losses stemming from these operational losses are calculated.

Outcomes:

Symptom 3

Reduced Earning per Head (EPH)

What are the causes?

This phenomenon often occurs in mature companies. Following a period of growth and profitability, companies may experience a decline in profitability, largely attributed to excessive overhead in processes. One of the underlying causes is the lack of standardization and rationalization in work practices, as well as a deficiency in multiskilling and job rotation within the organization. Additionally, inadequate protocols in recruitment processes can exacerbate this issue. During challenging periods, companies may need to streamline their workforce to achieve more with fewer resources.

Manpower Diagnosis

Key methods:

Process Study Motion Study Standardized Work Type I & III Work Combination Charts Yamazumi

Estimated Duration:

2 weeks (Dependent on the scale of the study)

A comprehensive diagnosis report is generated, estimating the manpower requirements using sampling work study techniques. This study assesses both direct and indirect workers to identify work elements, repetitive tasks, and interdependencies. Past data analysis and statistical methods are employed to determine the optimal workforce size for the organization.

Outcomes:

Symptom 4

Cultural Stagnation

What are the causes?

Culture in an organization reflects the way things are done, influenced by various factors including founder beliefs, leadership behavior, reward systems, company vision, processes, product management, people development, and team beliefs. Without intentional efforts to define culture, organic growth may lead to islands of excellence and people-driven processes, fostering power imbalances and organizational politics. Developing an XOS, or Your company (X) Operation System, is crucial to establish a unified operating system.

Lean Maturity Index

Estimated Duration:

4 Days

This comprehensive organizational diagnosis assesses both culture and process maturity levels across six key areas, benchmarking against world-class manufacturers like Toyota Motor Corporation. The assessment evaluates:

Outcomes:

Symptom 5

Hidden Cost in Digitalization

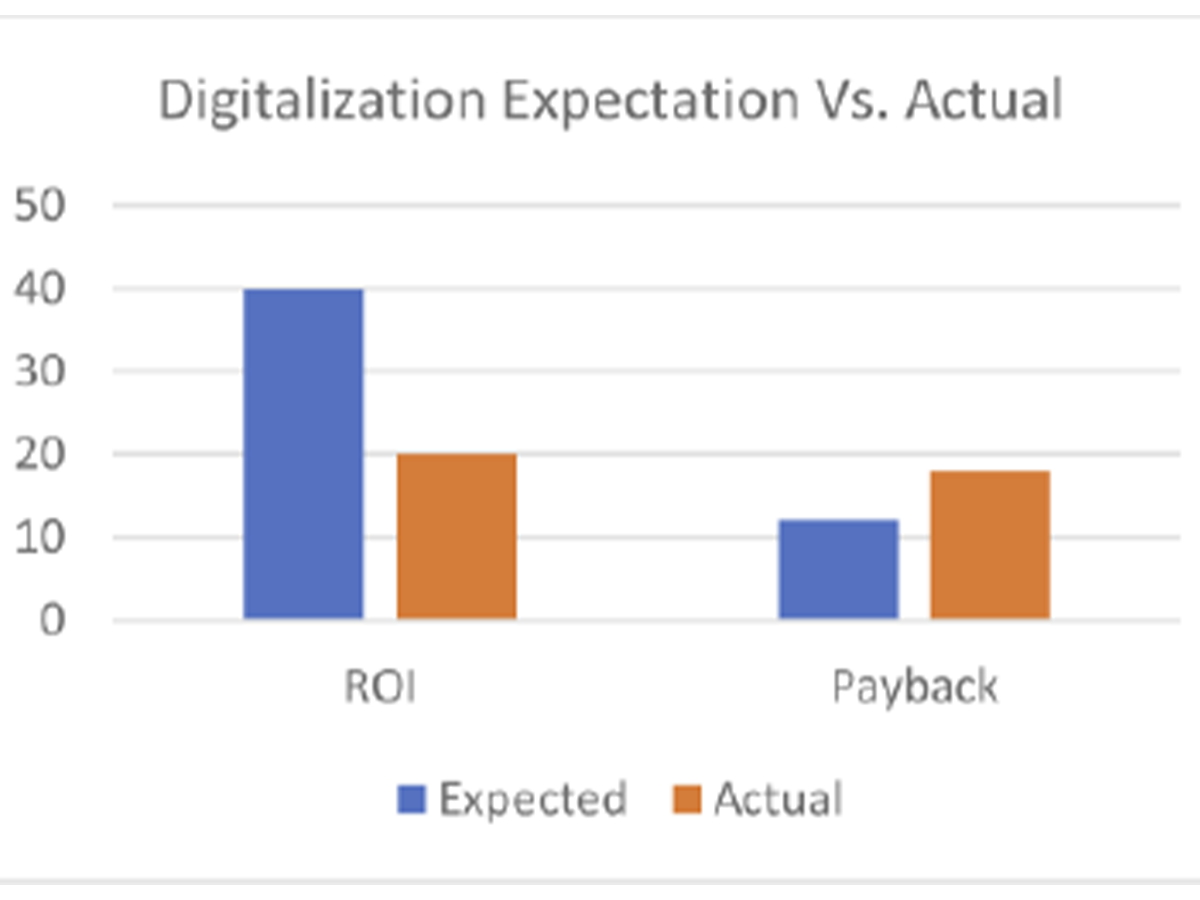

What are the causes?

Forbes has assessed the risk of failure in digital transformation to be as high as 84%. While digitalization is imperative, many companies fail to achieve anticipated success due to various factors, including inadequate change management, feasibility assessment, and resource planning, as well as incomplete requirement gathering. However, companies can mitigate risks and proactively address issues by conducting a comprehensive feasibility study before initiating digitalization efforts.

Digital Feasibility Study

Duration:

2 weeks

We offer a unique Digital Feasibility Study to understand the current state of processes and potential future states post-implementation. This study facilitates the estimation of payback, ROI, and resource change management efforts required for successful digitalization.