Lean Practitioner Green Belt Program

Lean Practitioner Green Belt Program for Corporate Teams

Best For

Senior & Middle Management

Delivery

10 Days | 5-6 Months. Conducted in Factory Premises

Training

Minimum 20 Participants per Company

Certified Lean Practitioner Green Belt Program

The Lean Practitioner Green Belt Program is a comprehensive training course designed to equip professionals with the skills and knowledge to implement Lean principles effectively within their organizations.

Tailored specifically for corporate teams, this program focuses on streamlining processes, reducing waste, and enhancing productivity.

Participants will gain practical experience through real-world projects, enabling them to drive continuous improvement and deliver measurable results in their workplace. This program is ideal for companies looking to foster a culture of efficiency and operational excellence.

Why Choose Our Lean Practitioner Green Belt ?

- Interactive coaching sessions with our experienced lean coaches

- Hands-on practical exercises, group discussions, individual and group projects to ensure maximum engagement

- ROI based project identification and setting up sustainable management system

- Instructors with 150+ collective experience in the apparel industry lean implementation

- Up to date curriculum aligned to ISO 18404 global standards

- Access to Center for Lean Online Learning Portal & Kaizen Management System

Training Content

Start with the basics of Lean principles, understanding the eight types of waste that hinder efficiency, and learn how to implement 5S and Gemba Kaizen to drive continuous improvement directly on the shop floor.

Gain insights into key Lean metrics and loss analysis techniques to effectively measure performance, identify inefficiencies, and implement improvements that enhance overall productivity.

Learn how to use Value Stream Mapping to visualize and analyze the flow of materials and information, while also identifying and assigning C.A.R.E (Collective Agreed Return Estimated) projects to maximize impact.

Explore the A3 Thinking process, a structured problem-solving approach, and learn how to create an A3 project report that clearly communicates the problem, analysis, and proposed solution.

Master the eight-step problem-solving process, a methodical approach to identifying, analyzing, and resolving issues in a way that ensures sustainable improvements.

Delve into process mapping techniques to achieve a deep understanding of your operations, allowing you to identify bottlenecks, streamline workflows, and improve efficiency.

Learn how to apply Lean principles to the new product development process to reduce time-to-market, along with mastering Quick Changeover (SMED) techniques to enhance flexibility and reduce downtime.

Understand the importance of Standardized Work to ensure consistency, efficiency, and quality, while also learning about Yamazumi (workload balancing) and effective Job Instruction Training techniques.

Discover strategies for building quality into every step of the production process, minimizing defects and ensuring that products meet high standards right from the start.

Learn the principles of TPM, a comprehensive approach to equipment maintenance that seeks to achieve perfect production by preventing breakdowns, defects, and accidents.

Explore the Pull System, specifically the Kanban method, to optimize inventory levels and ensure that production is closely aligned with customer demand.

Conclude the program with a final examination to test your knowledge, a Gemba Kaizen activity to apply what you’ve learned in a real-world setting, and an evaluation of your Lean projects to assess their effectiveness and impact.

Download Program Brochure

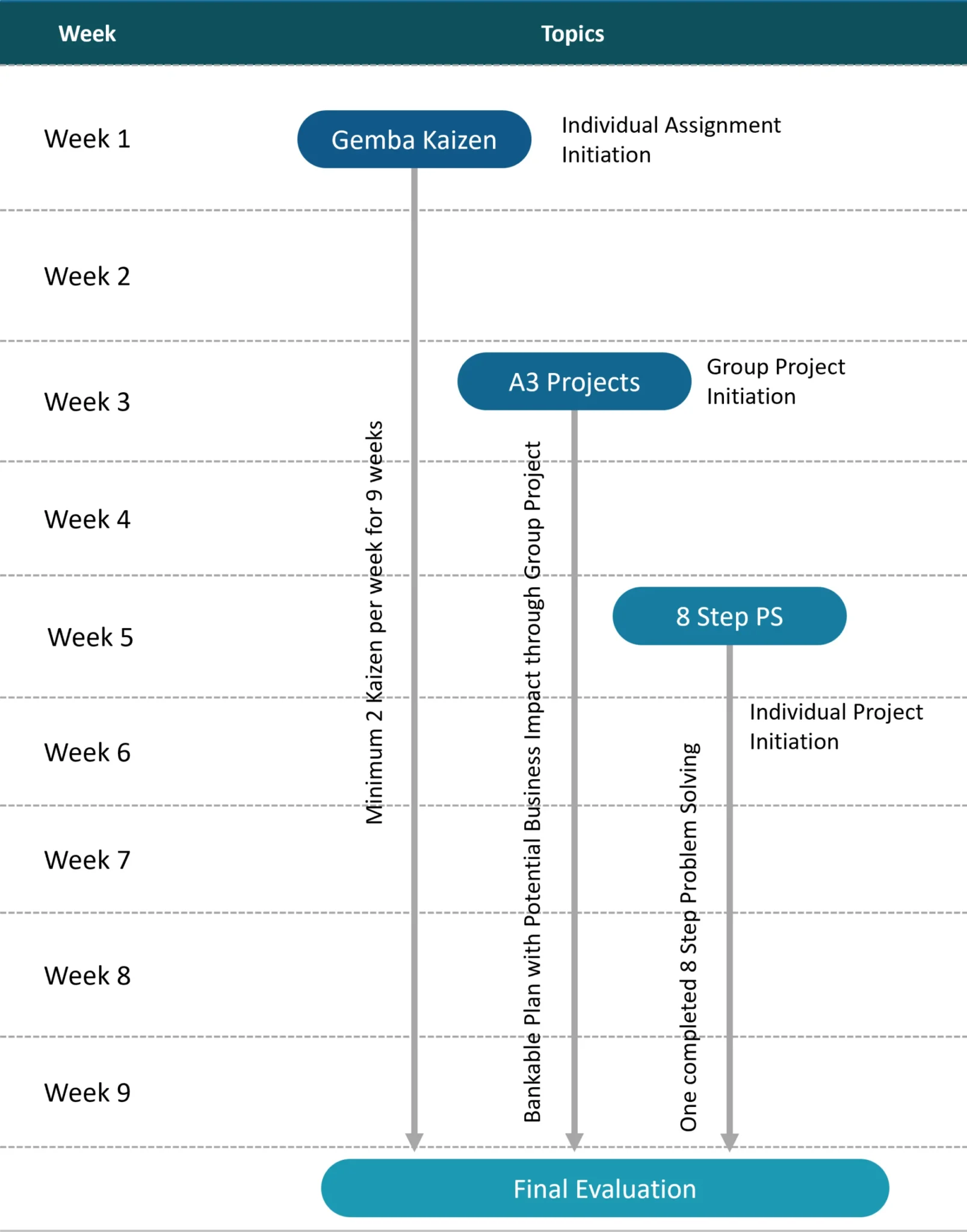

Practical Assignment Plan

Our program is designed to deliver tangible outcomes for your organization through a blend of group and individual assignments.

Participants will engage in practical applications of Gemba Kaizen, the 8-Step Problem Solving process, and A3 Project Execution, all aimed at achieving measurable savings and improvements in their respective work areas.

We emphasize hands-on learning, with 60% of the program’s evaluation based on these practical assignments.

These assignments are rigorously assessed by our experienced trainers onsite, ensuring that participants not only understand the concepts but also effectively apply them to drive real-world results.

Certification

Pass Criteria: To successfully complete the program, students must achieve a minimum score of 70% in all exams and project evaluations.

Digital Certification: Upon meeting the pass criteria, students will receive a digital certificate, signifying their successful completion of the course.

Printed Certificates: In addition to the digital certificate, students who pass will also receive printed dual certificates. These will be sent via postal services, issued by the Center for Lean Excellence, as a formal recognition of their achievement.

Access to Our Digital Portals

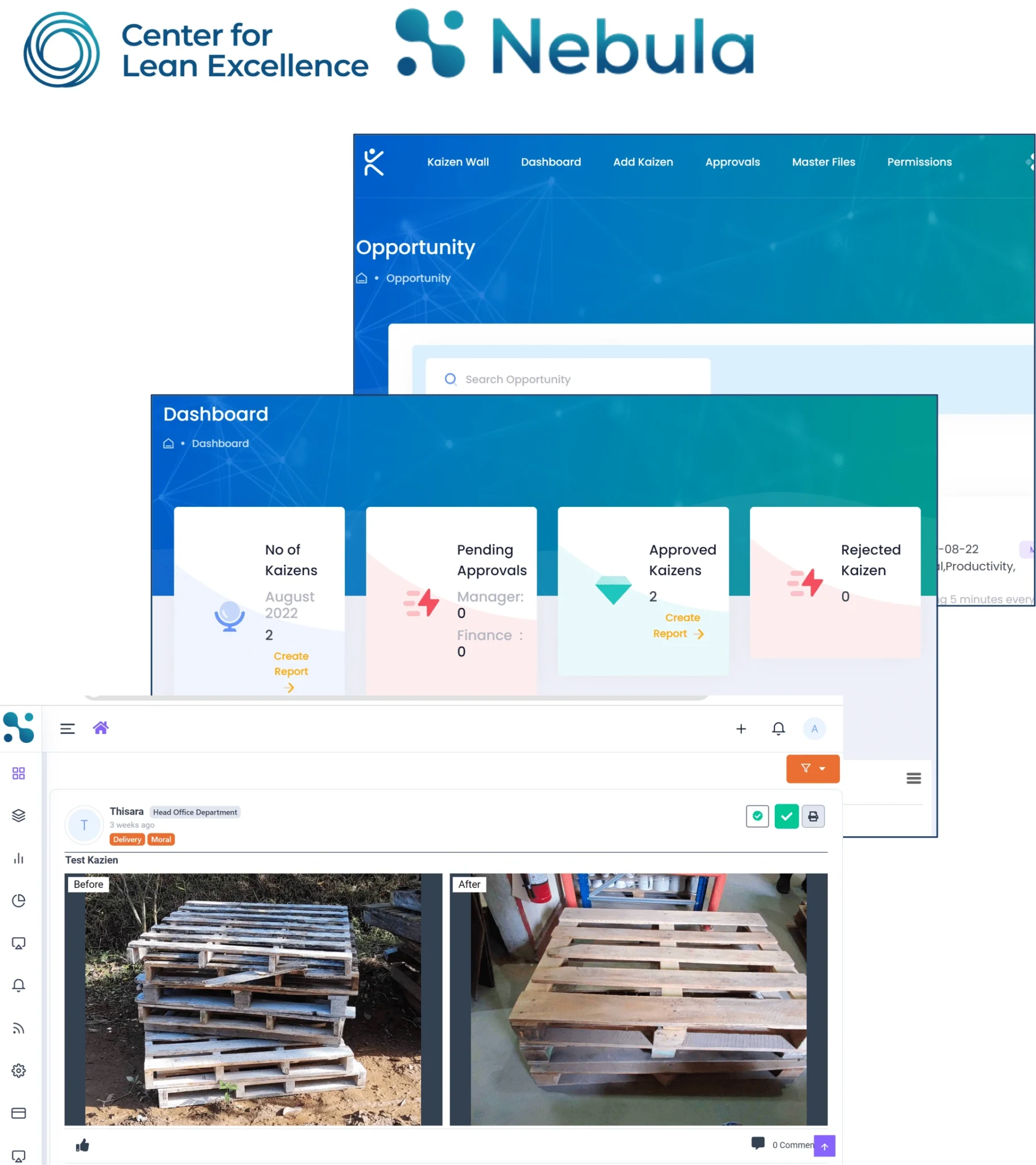

We are proud to introduce our Nebula Kaizen Management System and the Center for Lean Learning Portal—two powerful tools designed to enhance the Lean learning experience and maximize the impact of continuous improvement initiatives.

Nebula Kaizen Management System: This cutting-edge system provides a comprehensive platform to track and manage all Kaizen activities carried out by your team. It enables users to monitor the real-time impact of these continuous improvement efforts, offering insights into the tangible benefits achieved by trainees. The system ensures that every Kaizen is documented, evaluated, and its outcomes are visible, fostering a culture of transparency and accountability within the organization.

Center for Lean Learning Portal: Our online learning portal is the central hub for all course-related activities. It provides easy access to a wealth of learning materials, ensuring that participants have the resources they need to succeed. The portal also serves as the platform for conducting exams, enabling seamless assessment and evaluation. By integrating learning and evaluation into a single, user-friendly interface, the portal supports a cohesive and efficient learning experience