Future-Ready People

Future-Proof Processes

PROFESSIONAL TRAINING DEVELOPMENT

Advancing Lean Excellence through Japanese Manufacturing Wisdom

Learn directly from the principles that shaped the world’s most respected manufacturing systems.

What We Do

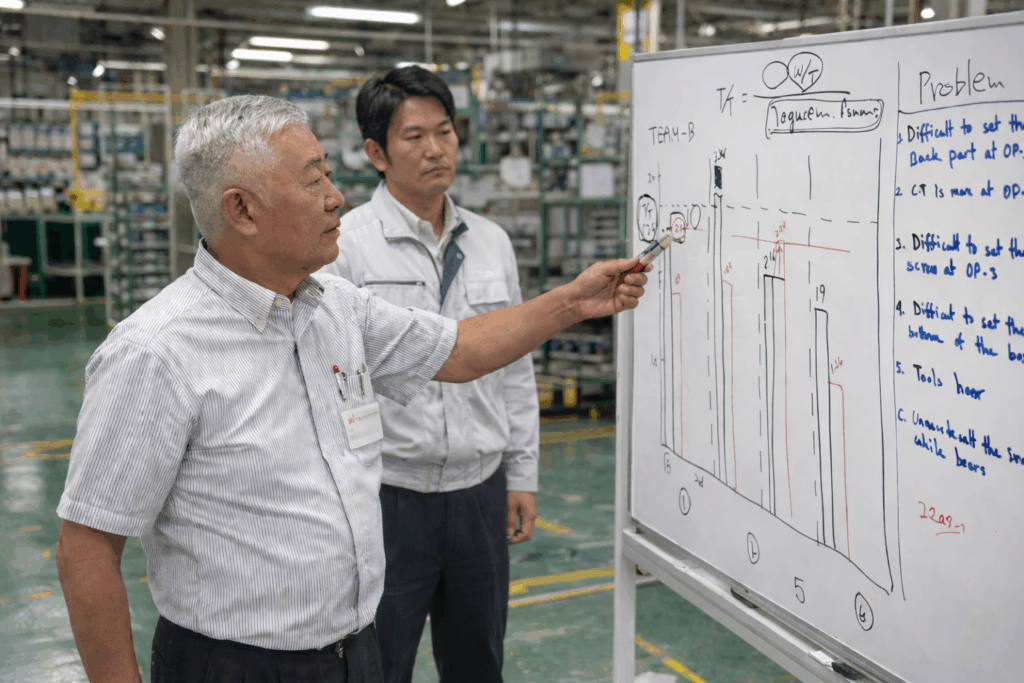

Lean Transformation & Training

We drive measurable business growth by applying Lean and Toyota Production System (TPS) principles that deliver lasting operational excellence.

Spread True TPS Knowledge

We transfer genuine Japanese Toyota Production System knowledge that enable leaders to lead sustainable transformation with confidence.

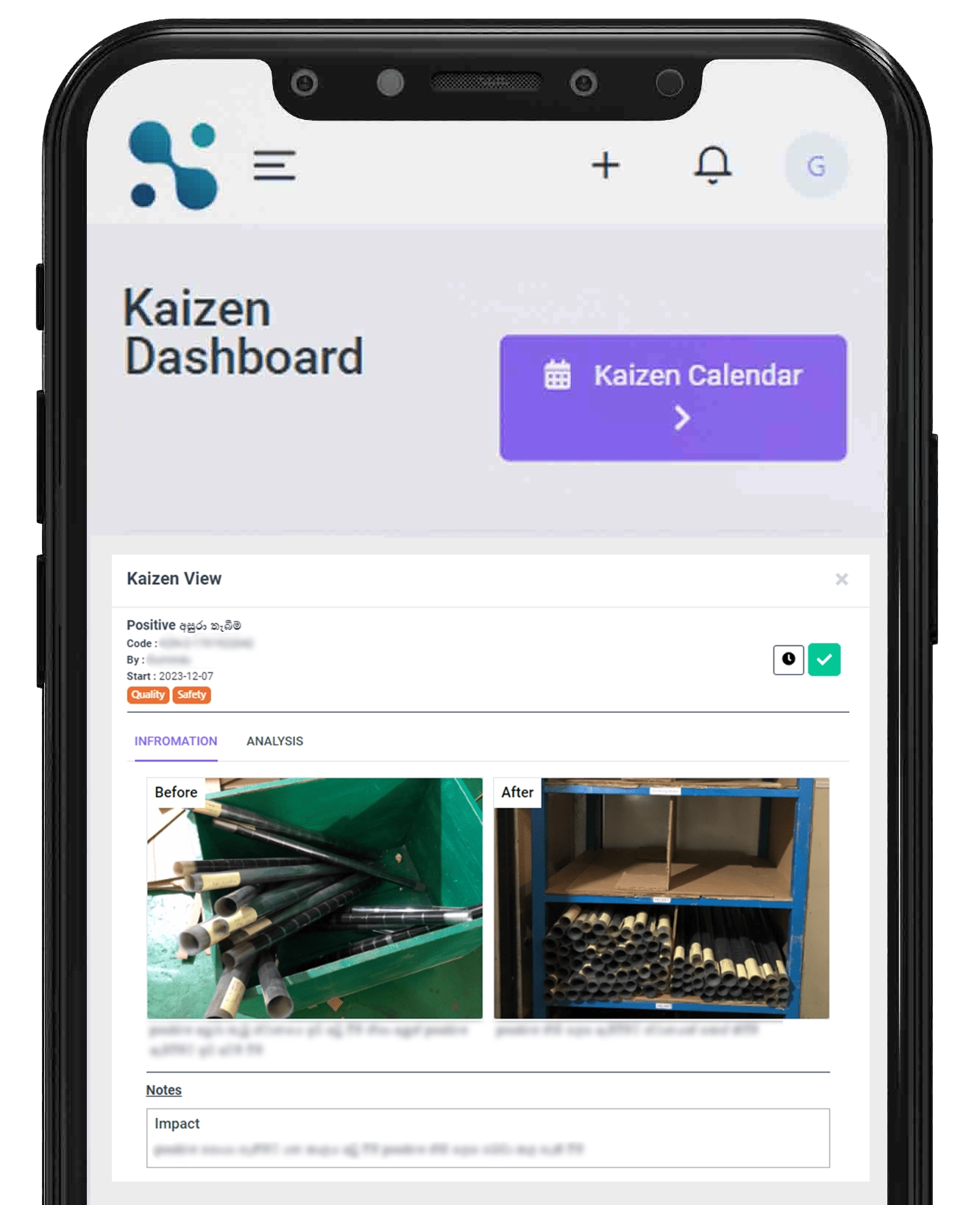

Custom Digital Lean Platforms

We design AI-powered digital solutions that simplify continuous improvement and accelerate Lean transformation across organizations.

Our Business Transformation Solutions

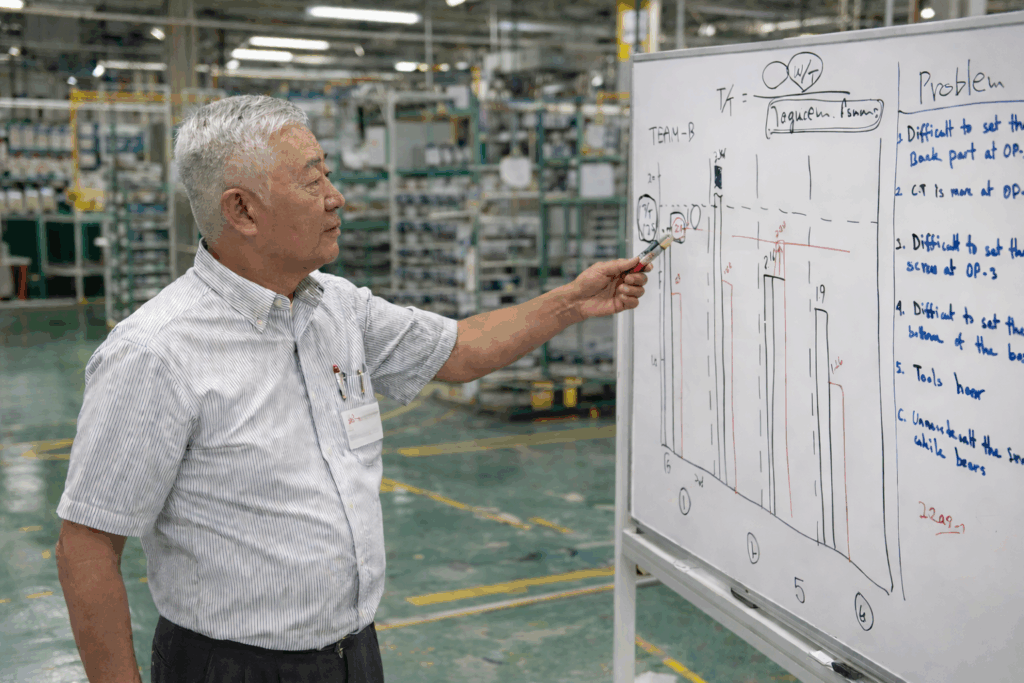

Factory Diagnosis

1-3 Months A comprehensive health check of your manufacturing process to qualitatively and quantitatively define its current state.

Lean Practitioner Green Belt

6 Months Upskill your management team’s capability with lean practical applications, ensuring a positive Return on Training Investment (ROTI)

Streamline Processes for Effective Digitalization

SPEED helps companies refine and simplify processes before digitalization, turning chaos into clarity and ensuring technology truly adds value.

Our Training Programs

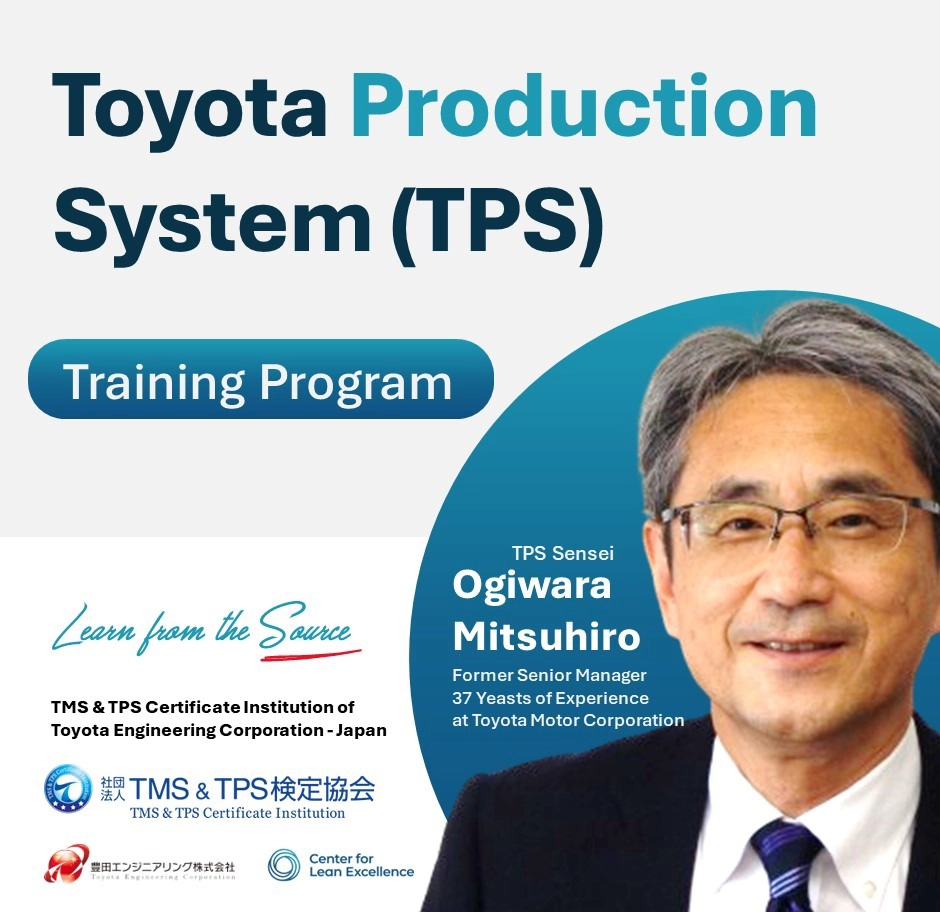

Toyota Production System (TPS) Certficate Program

Learn about Toyota manufacturing techniques and their practical application.

Toyota Management System (TMS) Training Program

Learn about Toyota leadership and management style

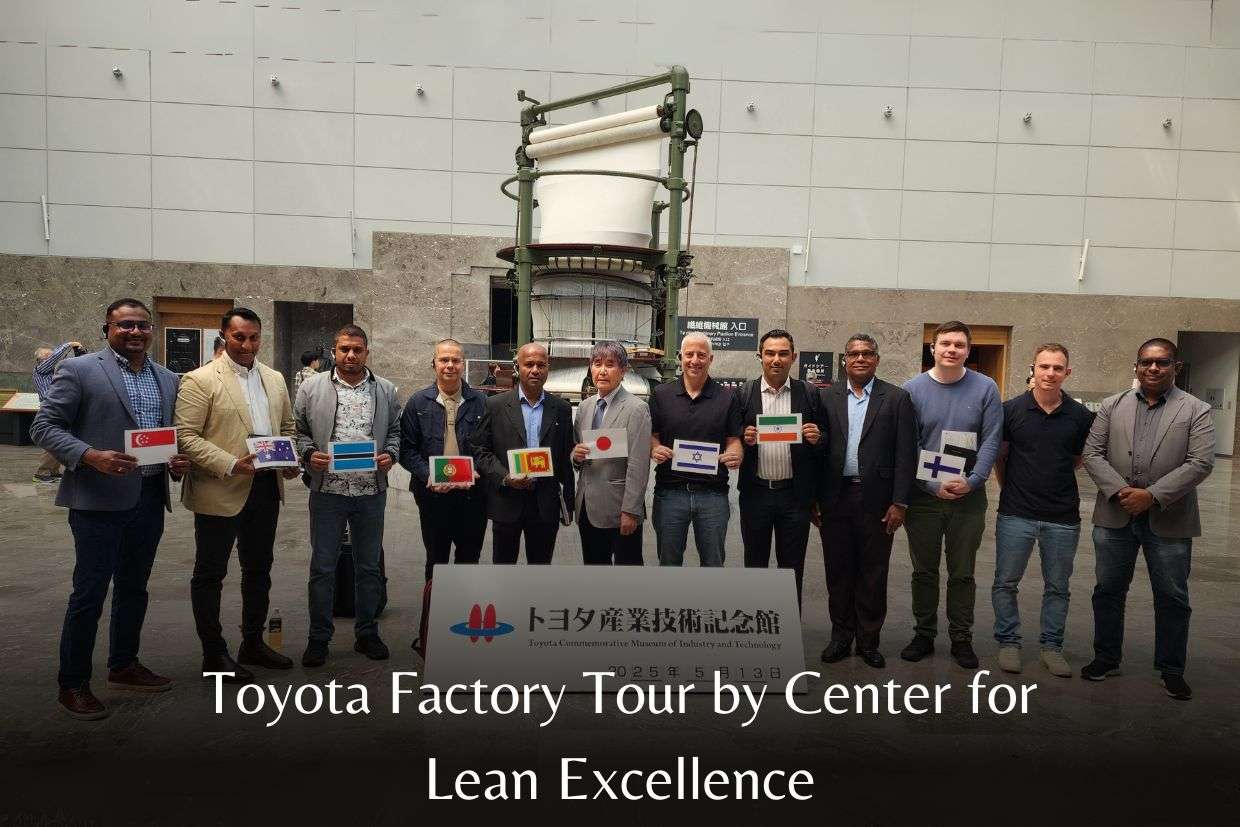

TPS Study Mission to Toyota Japan

Experience the Toyota Production System at its source. Join our immersive program in Japan featuring factory visits, expert-led workshops, and cultural insights to deepen your understanding of lean excellence.

Our Custom Digital Lean Platform

50% Less Work. 50% More Engagement

Enable your teams with a total Lean Operating System powered by AI. From managing Kaizen and facilitating Gemba walks to tracking improvement projects, it integrates every element of lean into one smart, connected platform for continuous transformation.

Our Versatility

Large-scale Projects

Textile Manufacturing

Food & Beverage

Logistics

Apparel

Porcelain

Tobacco

Tyre

Airlines

Agriculture

Paint

Software & BPR Industry

Bonding

Transformers

Rubber

Supply Chain

Our Clients

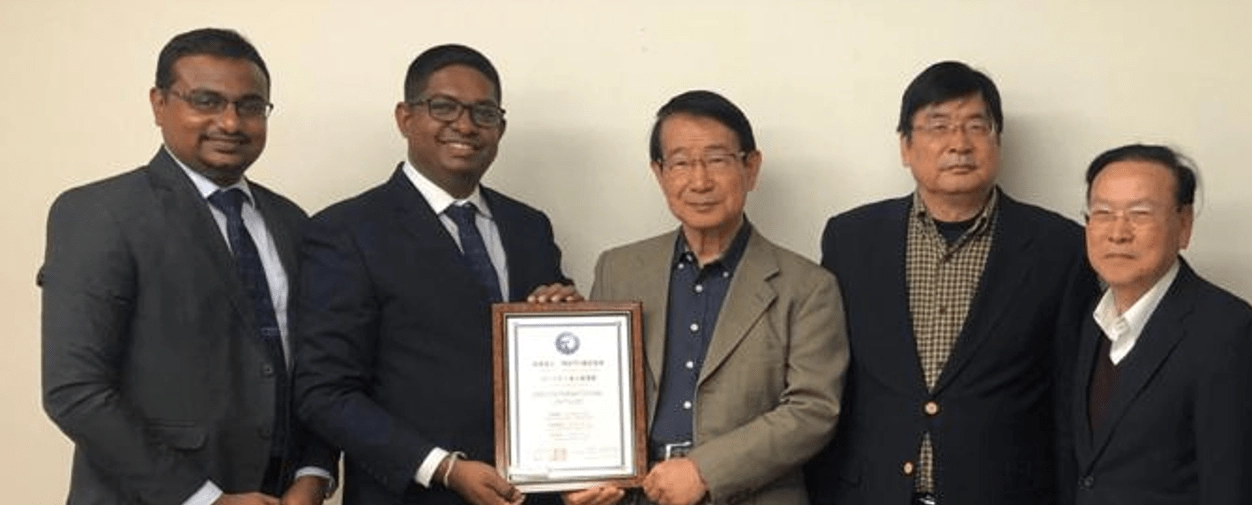

Our Corporate Partners

Toyota Engineering Corporation - Japan

Providing customized knowledge and solutions that works!

What is Lean Management?

Lean management is a widely accepted method of achieving operational excellence that is founded on a philosophy of maximizing productivity while minimizing waste during manufacturing or service operations. This is accomplished via the use of proven “lean management” methodologies. It is a strategic approach to provide optimum value to the customer considering the customer’s perspective, while consuming the fewest resources and utilizing the talents of the people who do the work. In the late 1980s, American scholars researched the famous Toyota Production System which was developed by Toyota Motor Corporation Japan. They discovered that the revolutionary manufacturing methodologies that are used in Toyota could be beneficial for any industry and coined the term “Lean Management” to refer this. Since then thousands of businesses in various industries across the world have adopted lean management methodologies to create significant productivity improvements in profitability, capacity, quality and employee morale.

Testimonials

Featured Articles

Read about what we do and what you can achieve as organizations and individuals with the help of us.

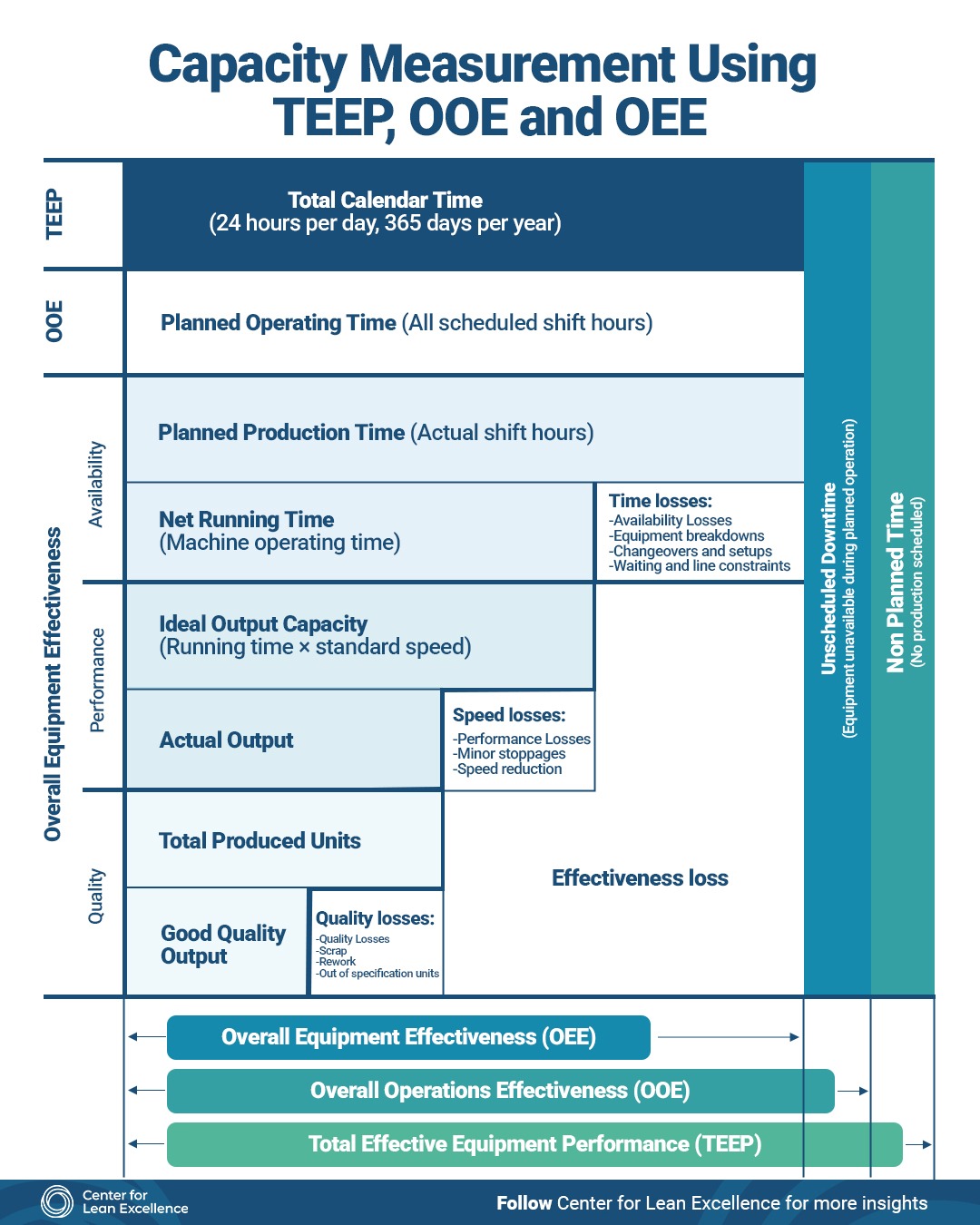

How TEEP, OOE and OEE Expose the Real Performance of Your Factory? In Lean manufacturing, capacity is often misunderstood. Many

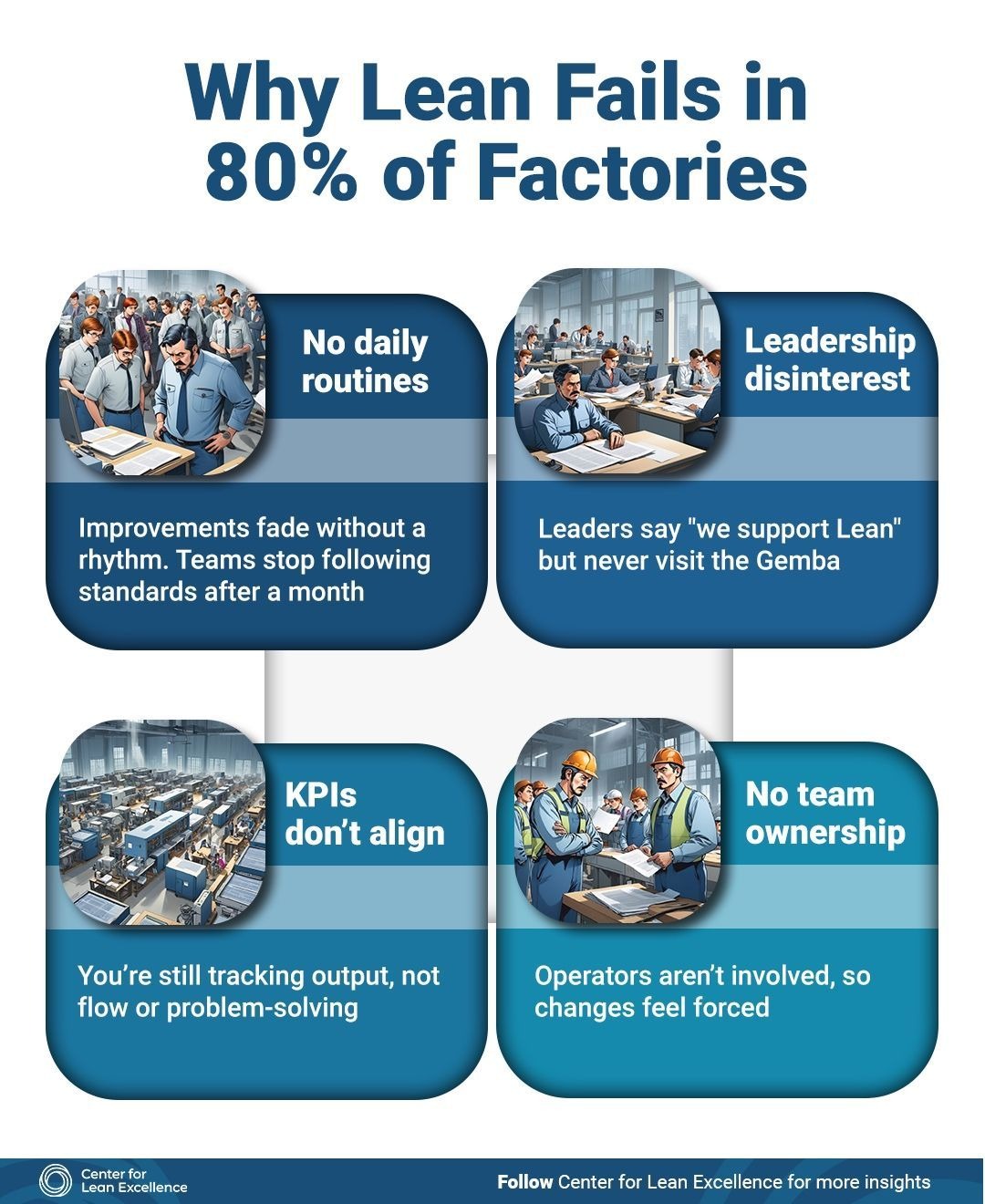

Lean has been discussed, taught, and implemented in manufacturing for decades. Why Lean Fails in 80% of Factories? Many organizations

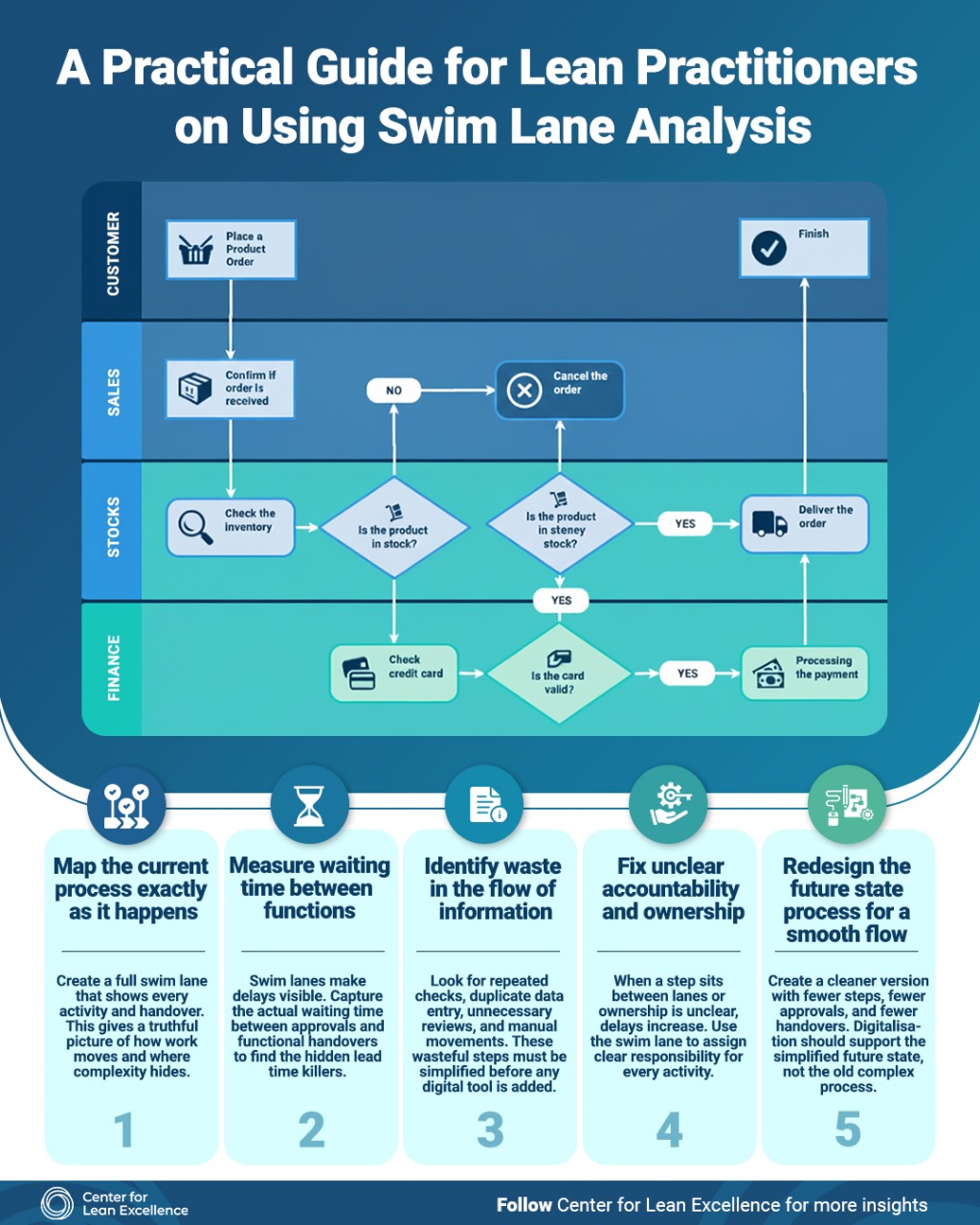

”How the Swim Lane Structure Reveals the True Workflow; Value of Swim Lane Analysis in Lean Practice.” In many organizations,

How ‘Reducing Lead Time’ Transforms Factory Performance? In modern manufacturing, speed is not just about machines running faster; it’s about

Discover the Role of Lean Consultant in Digital Transformation and why Lean experts are essential for reducing waste, aligning processes

Why One Clean Process Matter More Than 100 Software? In the race toward “digital transformation,” many organizations unknowingly create more

In every efficient manufacturing system, flow is the heartbeat of success. Whether you’re managing a production line, logistics, or service

Most organizations today believe they’ve become “digital.” They’ve invested in new tools, automated workflows and built data dashboards that track every

Subscribe for Our Newsletter

Join our community by signing up for our newsletter today!

Send Us a Message

Contact Us

Email:

hello@centerforlean.com

Phone:

+65 8684 9818 | +65 8684 9812 | +94778241664

Address:

10, Anson Road, #31-10, International Plaza, Singapore. 079903