Toyota Production System (TPS Grade IV) Certificate Program

by TMS TPS Certification Institute & Toyota Engineering Corporation Japan

Learn from the founders of Lean Management

Toyota Production System (TPS), also known as Lean Management is considered as the world’s most successful strategy for operational excellence. This methodology was born, raised and evolved at Toyota Motor Corporation in Japan for seven decades and is now being used as a strategic weapon for businesses, governments, and institutes around the world.

Toyota Engineering Corporation (TEC) was established in early 2000 to popularize the Total Toyota Production System or Lean Management across the world. Currently, they have certified more than 5000 professionals across the globe. The Lean Senseis at TEC possess decades of hands-on experience in developing, sustaining, and improving lean management concepts at Toyota and affiliated companies

TPS certification provides the most authentic, up to date, practical knowledge and application on Toyota Production System (Lean Management). Lean TPS Level IV certification is an essential step for manufacturing leaders to develop “must-know” practical skills in lean management.

BEST FOR

Leaders in the manufacturing sector

MATERIAL

TPS Text book

MODE

Instructor-led training (Executive TPS Sensei)

CERTIFICATE

Printed certificated from TMS TPS Certificate Institute- Japan

- Introduction: 14th Oct 2023

- Session 01: 21st Oct 2023

- Session 02: 28th Oct 2023

- Session 03: 4th Nov 2023

- Session 04: 11th Nov 2023

- Session 05: 18th Nov 2023

- Examination : 2nd Dec 2023

- Introduction: 20th Jan 2024

- Session 01: 27th Jan 2024

- Session 02: 3rd Feb 2024

- Session 03: 10th Feb 2024

- Session 04: 17th Feb 2024

- Session 05: 24th Feb 2024

- Examination : 9th March 2024

Download Program Brochure

“Studying the TPS system helped me to structure my working organization and prioritize my time on tasks for better results in my work life”

Yohann Autret

Batch 03 | February – April 2022

ECLOR Enterprises

Japan & Korea Sales Manager

Program Outcomes

- Revitalize your workforce to enforce sustainable continuous improvement culture in the organization

- Master the skill of "Genchi Genbutsu" (Go and See )

- Create breakthrough improvements in operations, logistics, machinery, development and quality assurance.

- Drive organization-wide change through management kaizen (Systematic Continuous Improvement)

- Become a competent change agent in organizational lean transformation

- Earn a globally recognized unique lean qualification from Toyota Engineering Corporation - Japan

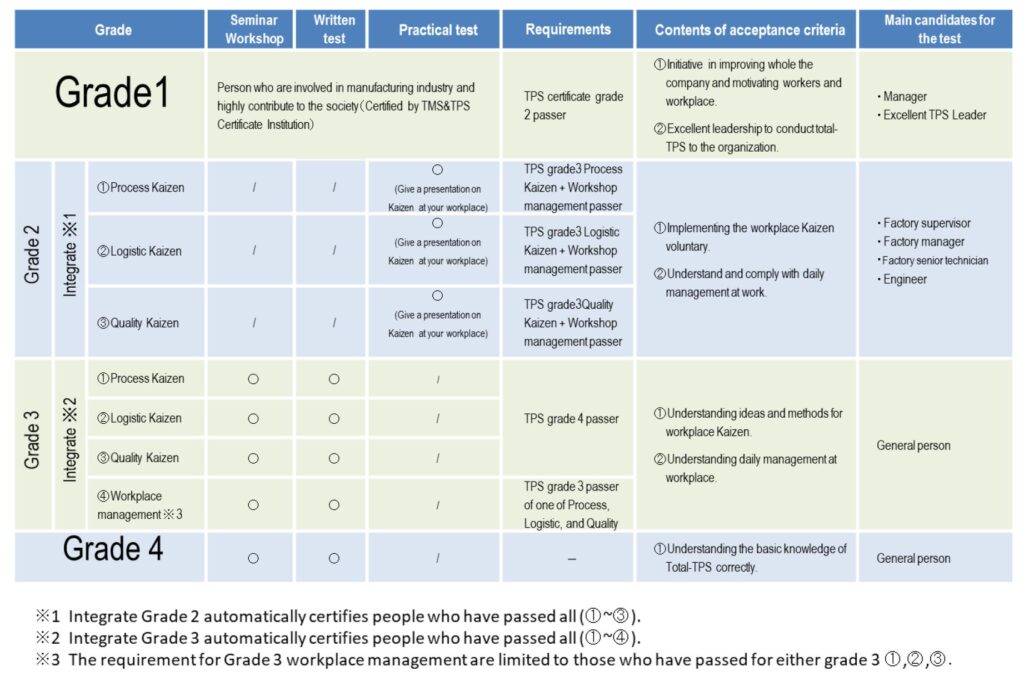

TPS Certification Journey

TPS Grade IV Program Content

- Day 01 (Conducted by the CLE Team)

- Introduction and Warm up Session

- Getting to know Lean Management

- Value, value-adding, and waste

- Setting up a lean manufacturing process in a new facility

- Value Stream Mapping for business

- Important points to know when implementing lean management

- Explanation of Lean Vocabulary

- Practical challenges of lean implementation and how to overcome

- Day 02

- Introduction to Toyota Production System (Lean Management), Just In Time & Jidoka

- The background of lean management and TPS

- Sharing value within the company

- Introduction to pull production

- The concept of JIDOKA

- Big lot production & Small lot production

- Q&A

- Day 03

- Simulation of workplace

- Quality Circles

- Multi skill development

- Suggestion systems

- Safety and Ergonomics

- Role of supervisors

- Human resource development

- Enhancement of welfare facilities

- Working environment preparation & improvement techniques

- Preparation and improvement of workplace

- Q&A

- Day 04

- 5S in revitalizing the workplace

- Kaizen examples

- Performance analysis board

- Pacemaker, Andon, Quality control board, Line with fixed position stopping system

- Stock control

- Preparation of operational standards

- Standardized production capacity sheet

- Working Instruction Sheet, Work Sequence Sheet

- Standard worksheet and Standardized Work combination Sheet

- Yamazumi Chart

- Quality Check Standard

- Q&A

- Day 05

- Kaizen in Operation

- Three factors of Standard work

- Elimination of Muda

- Operating rate and operational availability

- True efficiency and apparent efficiency

- Process lead-time reduction

- Kaizen in the production flow

- Leveled production (Heijunka), Large production, and Small lot production

- One-piece at a time production

- Kaizen in production layout (U shaped layout)

- The order of Kaizen

- Day 06

- Logistics Kaizen – Kanban System

- Frequent conveyance, Mixed load conveyance, Sequential part withdrawal, Parts withdrawal based on body production

- Material Handling in the plant

- Sequential parts loading (Jundate) , Grouping delivery, On-call Andon system, Grouping small parts, Containerless flow, Fixed course pick up system

- Kanban System

- Parts withdrawal kanban, Production instruction kanban

- 6 Rules of Kanban adoption

- KanbanManagement

- Deciding the number of kanbans

- Kanban calculation formula

- Equipment kaizen and TPM

- Advanced Kaizen and Simultaneous Engineering Activity

- QA Network

- Production Preparation

- Day 07 : Examination Day - Online

- TPS Grade IV Examination (80 MCQs | 60 Mins)

This Certification Program is Best Suited for

- Manufacturing Leaders who aspire to BEGIN Lean Transformation Journey

- Already qualified Lean Six Sigma Black-belts and Green-belts

- Entrepreneurs who want to develop a new dimension for their businesses

Transform Yourself Today!

- Investment : USD 795

* Postal / Courier charges will be separately billed for overseas participants

Contact us for more details:

Email : hello@centerforlean.com

Phone / Whatsapp : +94778241664 or +94777318299

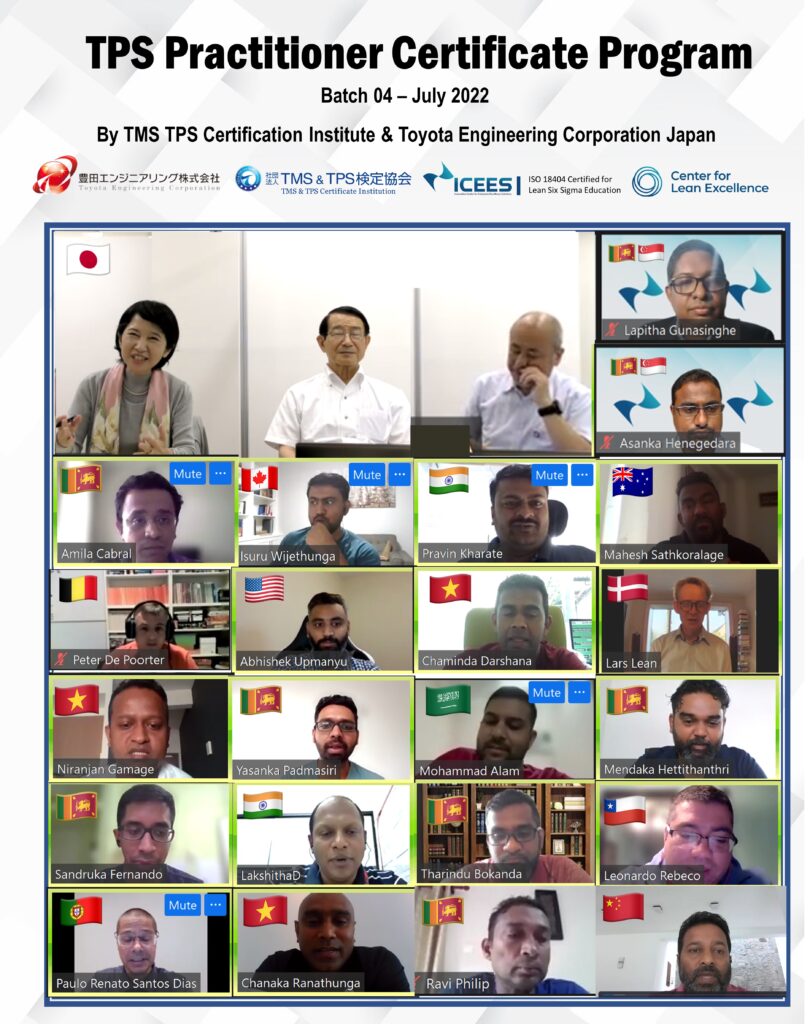

Join the Elite group of TPS Practitioners

Certified TPS Professionals Alumnus

Prestigious Certificate from Toyota Engineering Corporation

Learn from the WORLD'S BEST LEAN TPS Senseis

Meet Your Sensei

Ogiwara Mitsuhiro

Former Senior Manager with 37 Years of experience at Toyota Motor Corporation

2016 – 2019: Toyota Motor Corporation, Toyota, Japan

Administration Division, Plant Supporting Section, Motomachi Plant

2011 – 2015: Production Manager, Sichuan Toyota Motor Co., Ltd. (China):

Supervising manufacturing, production control and logistics

2008 – 2010: Assistant Project Section Manager

Global Production Center

2005 – 2008: Plant Manager

GAC Toyota Motor Co., Ltd.(China) Supervising production, quality control and manufacturing

2003 – 2004: Chief Expert : Global Production Center

Engaged in supporting the launch of a joint venture project with Guangzhou Automobile Group in China

1999-2002: Chief Expert Administration Division, Motomachi Plant

Engaged in supporting the launch of a joint venture project with Tianjin Automobile Industry Group in China

1995 – 1999: Chief Leader

Chassis Manufacturing Division, Honsha Plant

1991-1995: Production Engineering Division Ⅲ

Engaged in planning assembly process and promoting projects

1978-1991: Final Assembly Department, Honsha Plant

Engaged in controlling assembly line work as a member of Engineering Service Division

Join the Elite Group of 5000+ TPS Change Agents across the World !

TPS Grade System

Receive Your TPS Grade IV Hand Book to Your Door-step

Proudly Organized By

Center for Lean Excellence Solutions (CLE) is a process innovation solutions provider specializes on Lean (Toyota Production System), Six Sigma and Total Productive Maintenance (TPM) concepts. Our vision is to enable potential by pioneering transformation for the good of individuals and enterprises. We deliver knowledge and solutions with our expert team that collectively possess 130+ years of hands on experience on enterprise transformation. To bring first hand lean knowledge, CLE has partnered with Toyota Engineering Corporation in Japan.