Certified as a

Lean Leader Black Belt

Become a master of productivity

Certified as a

Lean Leader Black Belt

Become a master of productivity

What is Lean Leader Black Belt?

The Certified Lean Leader Black Belt sets a true north vision for the organization to achieve operational excellence. These efforts ensure optimum customer value creation while eliminating non-value-adding activities in the operations to pursue maximum profitability. Lean Leader Black Belts continuously strive to identify value stream level improvement opportunities, develop continuous improvement behaviors, establish daily management routines, and promote systematic problem-solving at every level of the organization.

What is Lean Leader black belt?

The Certified Lean Leader Black Belt sets a true north vision for the organization to achieve operational excellence. These efforts ensure optimum customer value creation while eliminating non-value-adding activities in the operations to pursue maximum profitability. Lean Leader Black Belts continuously strive to identify value stream level improvement opportunities, develop continuous improvement behaviors, establish daily management routines, and promote systematic problem-solving at every level of the organization.

What is Lean Leader black belt?

The Certified Lean Leader Black Belt sets a true north vision for the organization to achieve operational excellence. These efforts ensure optimum customer value creation while eliminating non-value-adding activities in the operations to pursue maximum profitability. Lean Leader Black Belts continuously strive to identify value stream level improvement opportunities, develop continuous improvement behaviors, establish daily management routines, and promote systematic problem-solving at every level of the organization.

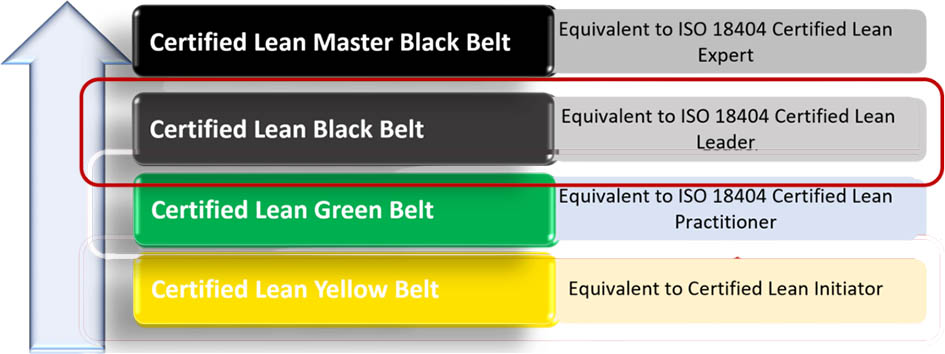

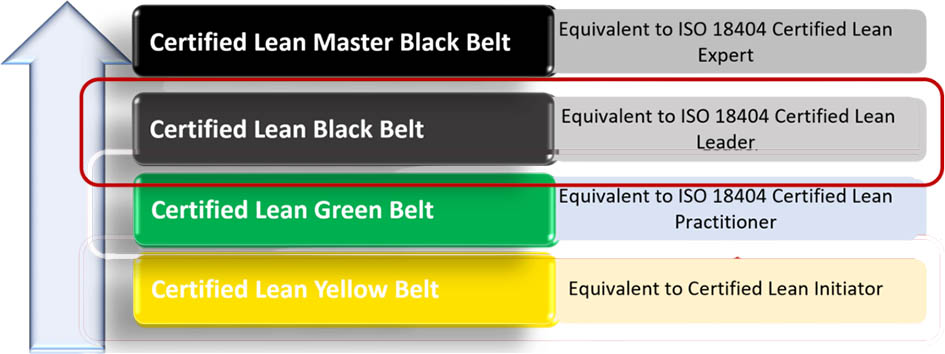

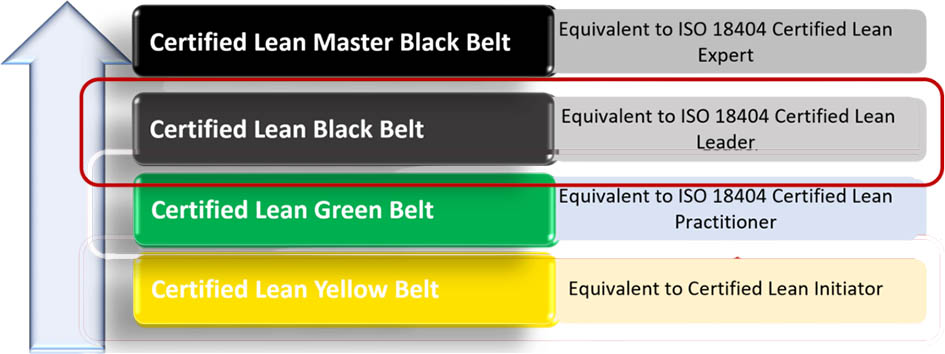

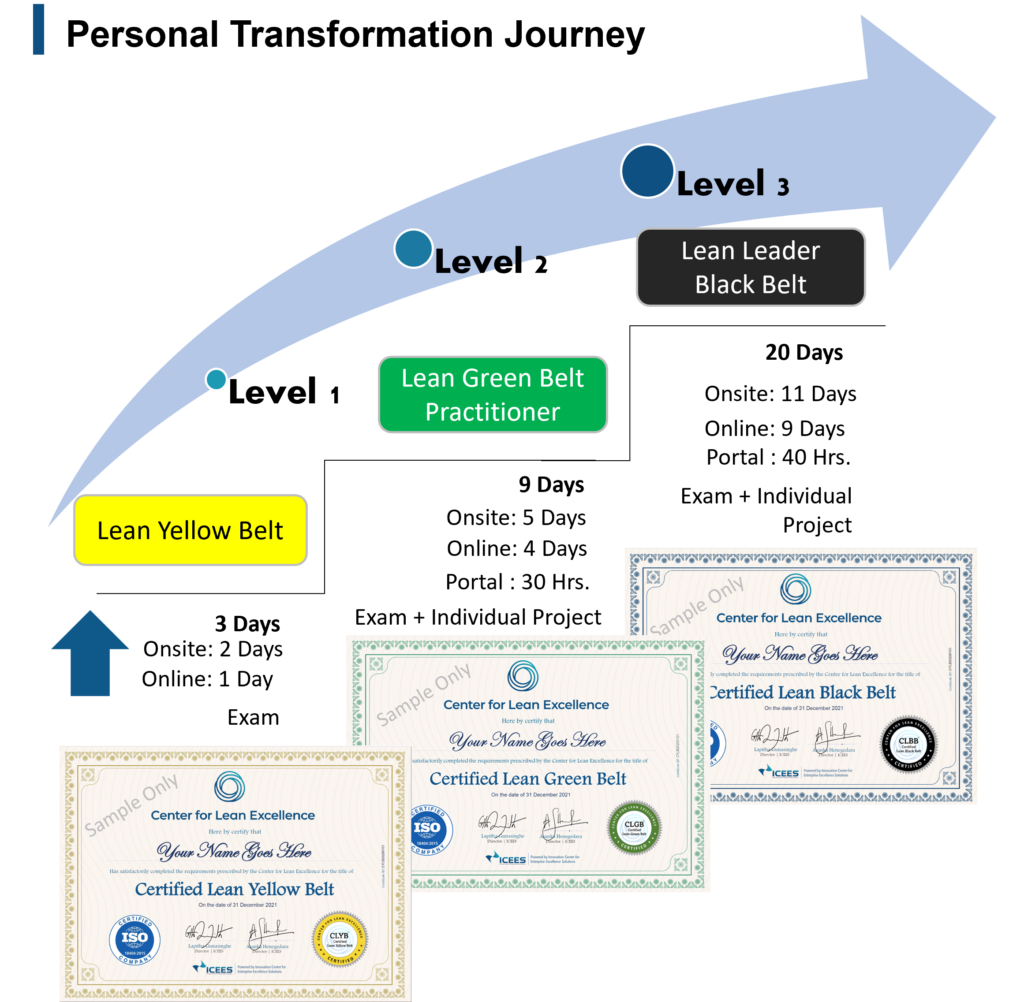

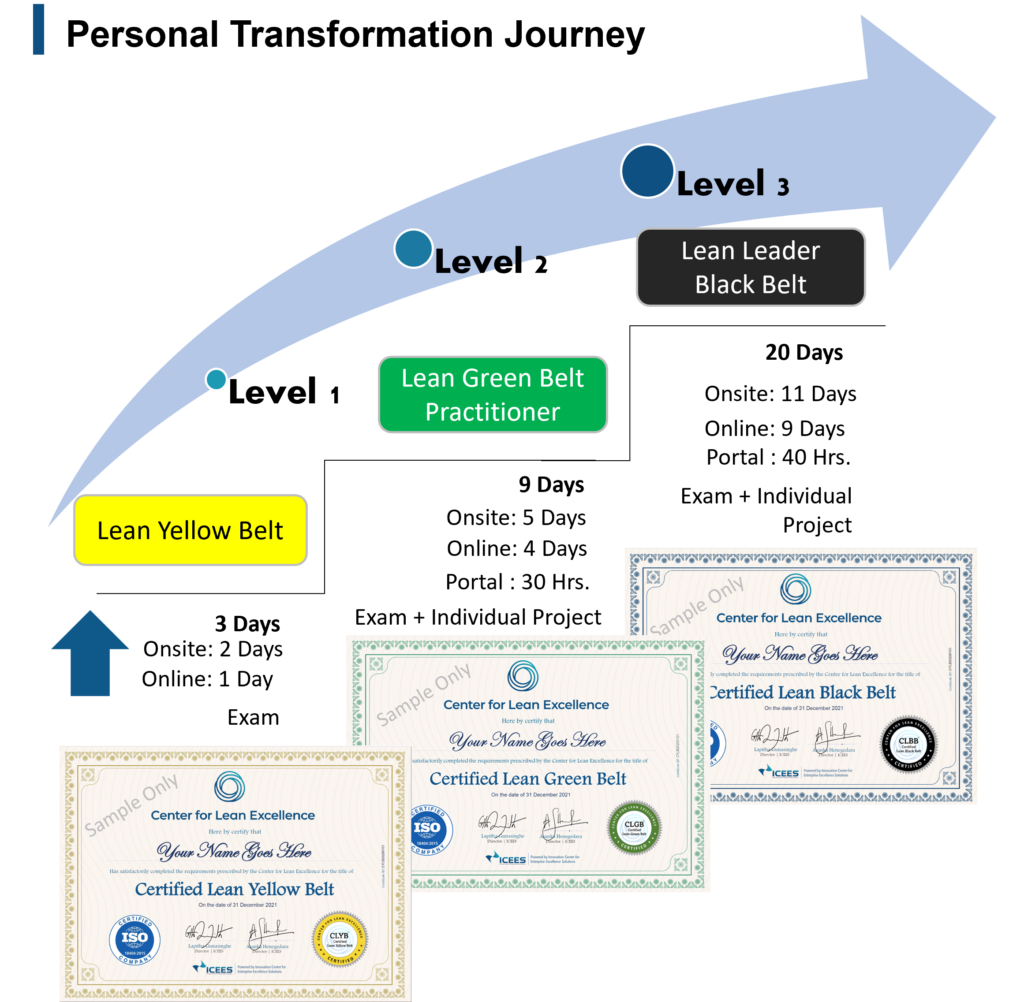

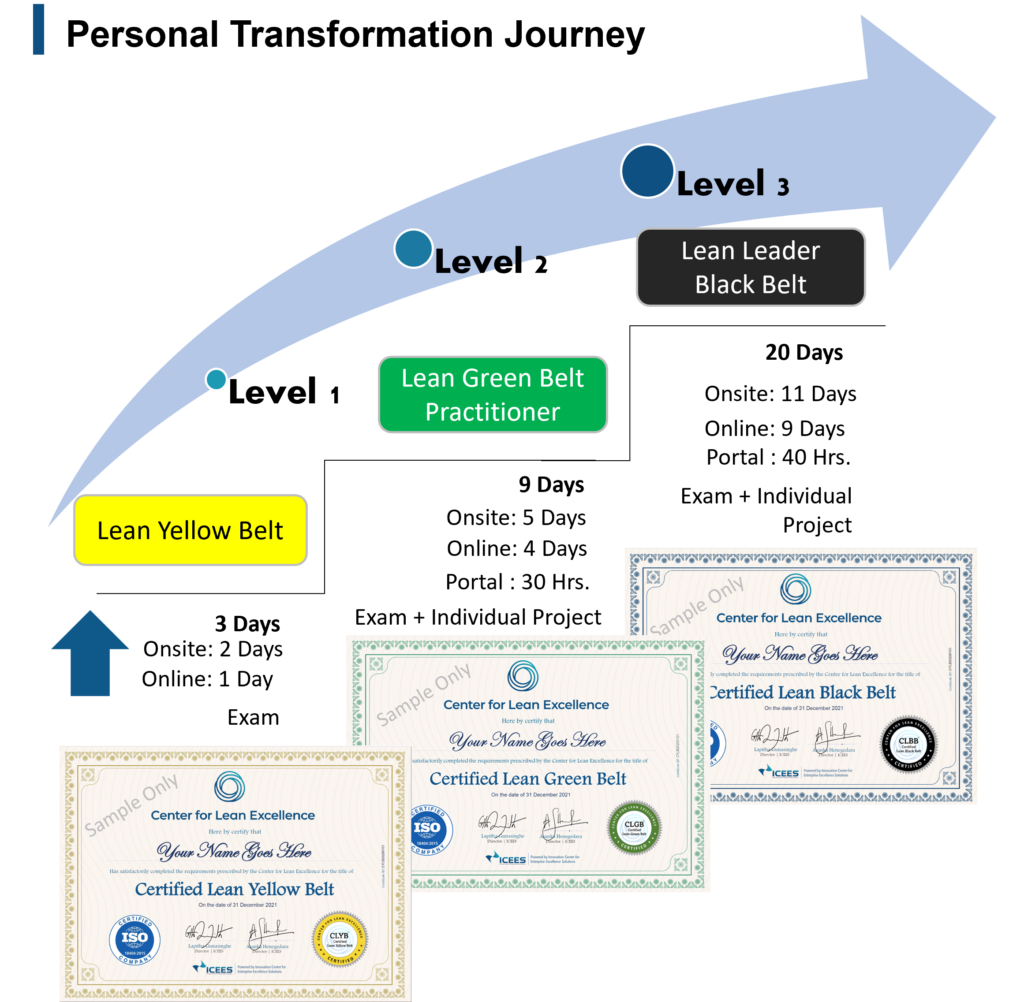

Lean Certification Levels (18404)

Lean Certification Levels (18404)

Lean Certification Levels (18404)

Best For

Leaders in the manufacturing sector

Delivery

11 Days Onsite

9 Days Online

40 Hours Portal

Total of 20 Days

Material

Pdf Study Materials are

provided

Mode

Instructor-led with an executive coach

Certificate

Printed certificated from Center for Lean Excellence

Register for Next Intake

Get you registered and take the opportunity to achieve globally recognized lean management black belt certification training conduct by the industry experts. In this program, you can interact with the instructors through both online and offline sessions and our staff consists of instructors with 150+ collective experience in the lean implementation. The course provides phase-wise guidance on organization lean transformation and the UpToDate curriculum is aligned with respect to ISO 18404 global standards.

Register for Next Intake

Get you registered and take the opportunity to achieve globally recognized lean management black belt certification training conduct by the industry experts. In this program, you can interact with the instructors through both online and offline sessions and our staff consists of instructors with 150+ collective experience in the lean implementation. The course provides phase-wise guidance on organization lean transformation and the UpToDate curriculum is aligned with respect to ISO 18404 global standards.

Next Program

- Next Program Start Date : May 2023

- Time : 9:00 am to 5:00 pm

- Duration : 5 Months

- Onsite Learning : 11 Days

- Online Instructor Led Learning : 9 Days (Zoom)

- Coaching : Individual coaching time slots to be allocated

Suits for

The coveted program conducted by the Center for Lean Excellence Singapore is highly recommended for Directors and Senior Managers. The entire program will take 140 learning hours and will include Live Online & Onsite Practical as well.

In order to be qualified to follow the Lean Leader black belt, you require the Lean Practitioner Green Belt. Last but not least, you will be evaluated via exams and individual & group assignments. If you feel that this is the right course for you to follow, click on “Register Now”.

Next Program

- Next Program Start Date : May 2023

- Time : 9:00 am to 5:00 pm

- Duration : 5 Months

- Onsite Learning : 11 Days

- Online Instructor Led Learning : 9 Days (Zoom)

- Coaching : Individual coaching time slots to be allocated

Suits for

The coveted program conducted by the Center for Lean Excellence Singapore is highly recommended for Directors and Senior Managers. The entire program will take 140 learning hours and will include Live Online & Onsite Practical as well.

In order to be qualified to follow the Lean Leader Black Belt, you require the Lean Practitioner Green Belt. Last but not least, you will be evaluated via exams and individual & group assignments. If you feel that this is the right course for you to follow, click on “Register Now”.

Next Program

- Next Program Start Date : May 2023

- Time : 9:00 am to 5:00 pm

- Duration : 5 Months

- Onsite Learning : 11 Days

- Online Instructor Led Learning : 9 Days (Zoom)

- Coaching : Individual coaching time slots to be allocated

Suits for

The coveted program conducted by the Center for Lean Excellence Singapore is highly recommended for Directors and Senior Managers. The entire program will take 140 learning hours and will include Live Online & Onsite Practical as well.

In order to be qualified to follow the Lean Leader black belt, you require the Lean Practitioner Green Belt. Last but not least, you will be evaluated via exams and individual & group assignments. If you feel that this is the right course for you to follow, click on “Register Now”.

Program

Becoming certified in Lean Leader Black Belt program can open up a plethora of new career opportunities and an accompanying salary increase.

Program Outcomes

- Practical guidance to see waste, eleminate waste and continuously improve

- Step by step approach to improve company profitability though application of lean techniques

- Ability to be coached and mentored by experienced lean transformation coaches

- Fully customized training after analyzing the current status and the purpose of implementation

- Detailed and simple practitioner notes and practical format kit

- Globally recognized certificate from Center for Lean Excellence

Program

Becoming certified in Lean Leader Black Belt program can open up a plethora of new career opportunities and an accompanying salary increase.

Program Outcomes

- Practical guidance to see waste, eleminate waste and continuously improve

- Step by step approach to improve company profitability though application of lean techniques

- Ability to be coached and mentored by experienced lean transformation coaches

- Fully customized training after analyzing the current status and the purpose of implementation

- Detailed and simple practitioner notes and practical format kit

- Globally recognized certificate from Center for Lean Excellence

Program

Becoming certified in Lean Leader Black Belt program can open up a plethora of new career opportunities and an accompanying salary increase.

Program Outcomes

- Practical guidance to see waste, eleminate waste and continuously improve

- Step by step approach to improve company profitability though application of lean techniques

- Ability to be coached and mentored by experienced lean transformation coaches

- Fully customized training after analyzing the current status and the purpose of implementation

- Detailed and simple practitioner notes and practical format kit

- Globally recognized certificate from Center for Lean Excellence

Leadership Development Solutions

Center for Lean Excellence

Leadership Development Solutions

Center for Lean Excellence

Standard Curriculum

- Introduction to Lean, 8 Types of Wastes, 5S for Productivity, Gemba Kaizen

- Process Mapping, Lean Metrices, Lean Problem-solving Techniques (Basic Tools)

- Role of the TM and Supervisor, Lean Change Management, Visual Management (Visual Pyramid), Meeting Facilitation, Quality Circles & presentation skills

- A3 Thinking, 8 Step problem Solving & Initiate Project 1

- Yamazumi and Layout Preparation, STW, JIT, Multiskilling & Training School, Safety & Ergonomics, AM & PM (Part 1), 5 Day Kaizen Activity

- Assembly-line Simulation

- Value Stream Mapping & Current & Future (Intro Level), Lean New Product Development, QCO, Chassis model and PCU

- Product Development Simulation

- Value Stream Mapping (Deep), Pull System Kanban, Production planning and control, Hijunka, Inventory Management

- Value Stream Map Simulation

- BIQ and M&I flow mapping, Quality Support Metrix, Error proofing & Self Ownership, Human Value Stream

- Built In Quality Simulation

- Hoshin Kanri

- Lean Leadership, Daily management & Kamishibi, Jishuken, Supplier Integration, Chassis model and PCU, AM & PM (Advanced)

- Change Management, Automation, Digitization Industry 4.0

Evaluation Criteria

- All students must complete the exam at the Center for Excellence Learning Portal. https://learn.centerforlean.com

- Examination: 100 questions (MCQ type) to be answered in 80 minutes

- Minimum pass score is 70%

- Maximum 3 attempts allowed (In an event where the student is unable to score more than 70% for a quiz, then the student will have to subscribe again to the examination by paying the due amount)

- The student must complete the 3 attempts within 3 months from the date of subscription. The examination link expires after 3 months. If the student was unable to complete the course during the 3 months, then he/she will have to subscribe again to the program

Standard Curriculum

- Introduction to Lean, 8 Types of Wastes, 5S for Productivity, Gemba Kaizen

- Process Mapping, Lean Metrices, Lean Problem-solving Techniques (Basic Tools)

- Role of the TM and Supervisor, Lean Change Management, Visual Management (Visual Pyramid), Meeting Facilitation, Quality Circles & presentation skills

- A3 Thinking, 8 Step problem Solving & Initiate Project 1

- Yamazumi and Layout Preparation, STW, JIT, Multiskilling & Training School, Safety & Ergonomics, AM & PM (Part 1), 5 Day Kaizen Activity

- Assembly-line Simulation

- Value Stream Mapping & Current & Future (Intro Level), Lean New Product Development, QCO, Chassis model and PCU

- Product Development Simulation

- Value Stream Mapping (Deep), Pull System Kanban, Production planning and control, Hijunka, Inventory Management

- Value Stream Map Simulation

- BIQ and M&I flow mapping, Quality Support Metrix, Error proofing & Self Ownership, Human Value Stream

- Built In Quality Simulation

- Hoshin Kanri

- Lean Leadership, Daily management & Kamishibi, Jishuken, Supplier Integration, Chassis model and PCU, AM & PM (Advanced)

- Change Management, Automation, Digitization Industry 4.0

Evaluation Criteria

- All students must complete the exam at the Center for Excellence Learning Portal. https://learn.centerforlean.com

- Examination: 100 questions (MCQ type) to be answered in 80 minutes

- Minimum pass score is 70%

- Maximum 3 attempts allowed (In an event where the student is unable to score more than 70% for a quiz, then the student will have to subscribe again to the examination by paying the due amount)

- The student must complete the 3 attempts within 3 months from the date of subscription. The examination link expires after 3 months. If the student was unable to complete the course during the 3 months, then he/she will have to subscribe again to the program

Standard Curriculum

- Introduction to Lean, 8 Types of Wastes, 5S for Productivity, Gemba Kaizen

- Process Mapping, Lean Metrices, Lean Problem-solving Techniques (Basic Tools)

- Role of the TM and Supervisor, Lean Change Management, Visual Management (Visual Pyramid), Meeting Facilitation, Quality Circles & presentation skills

- A3 Thinking, 8 Step problem Solving & Initiate Project 1

- Yamazumi and Layout Preparation, STW, JIT, Multiskilling & Training School, Safety & Ergonomics, AM & PM (Part 1), 5 Day Kaizen Activity

- Assembly-line Simulation

- Value Stream Mapping & Current & Future (Intro Level), Lean New Product Development, QCO, Chassis model and PCU

- Product Development Simulation

- Value Stream Mapping (Deep), Pull System Kanban, Production planning and control, Hijunka, Inventory Management

- Value Stream Map Simulation

- BIQ and M&I flow mapping, Quality Support Metrix, Error proofing & Self Ownership, Human Value Stream

- Built In Quality Simulation

- Hoshin Kanri

- Lean Leadership, Daily management & Kamishibi, Jishuken, Supplier Integration, Chassis model and PCU, AM & PM (Advanced)

- Change Management, Automation, Digitization Industry 4.0

Evaluation Criteria

- All students must complete the exam at the Center for Excellence Learning Portal. https://learn.centerforlean.com

- Examination: 100 questions (MCQ type) to be answered in 80 minutes

- Minimum pass score is 70%

- Maximum 3 attempts allowed (In an event where the student is unable to score more than 70% for a quiz, then the student will have to subscribe again to the examination by paying the due amount)

- The student must complete the 3 attempts within 3 months from the date of subscription. The examination link expires after 3 months. If the student was unable to complete the course during the 3 months, then he/she will have to subscribe again to the program

Program Content

Lean Leader Black Belt training and certification ISO 18404 certified curriculum is consist of the content must-have for advance Lean practitioners who want to become the experts in Lean implementation.

Program Content

Lean Leader Black Belt training and certification ISO 18404 certified curriculum is consist of the content must-have for advance Lean practitioners who want to become the experts in Lean implementation.

Session 02 (Online)

- Process Mapping,

- Lean Metrices

- Lean Problem-solving Techniques (Basic Tools)

Session 03 (Online)

- Role of the Team member and Supervisor

- Lean Change Management

- Visual Management (Visual Pyramid)

- Meeting Facilitation

- Quality Circles & presentation skills

Session 02 (Online)

- Process Mapping,

- Lean Metrices

- Lean Problem-solving Techniques (Basic Tools)

Session 03 (Online)

- Role of the Team member and Supervisor

- Lean Change Management

- Visual Management (Visual Pyramid)

- Meeting Facilitation

- Quality Circles & presentation skills

Session 06 (Online)

- Yamazumi and Layout Preparation

- STW, JIT, Multiskilling

- Training School

- Safety & Ergonomics

- AM & PM (Part 1)

- 5 Day Kaizen Activity

Session 06 (Online)

- Yamazumi and Layout Preparation

- STW, JIT, Multiskilling

- Training School

- Safety & Ergonomics

- AM & PM (Part 1)

- 5 Day Kaizen Activity

Session 07 (Onsite Practical)

- Assembly line simulation activityat Hotel Galadari Simulated Factory

Session 08 (Online)

- Value Stream Mapping & Current & Future (Intro Level)

- Lean New Product Development

- Quick Changeover

- Chassis model and PCU

Session 09 (Onsite Practical)

- Practical Simulation Session on Product Development at Simulated Factory at Hotel Galadari Colombo

Session 07 (Onsite Practical)

- Assembly line simulation activityat Hotel Galadari Simulated Factory

Session 08 (Online)

- Value Stream Mapping & Current & Future (Intro Level)

- Lean New Product Development

- Quick Changeover

- Chassis model and PCU

Session 09 (Onsite Practical)

- Practical Simulation Session on Product Development at Simulated Factory at Hotel Galadari Colombo

Session 10 (Exam & Project Review)

- Examination 2- MCQ Type online exam

- Review the project on 8 Step Problem Solving

Session 11 (Online)

- Value Stream Mapping (Deep)

- Pull System Kanban

- Production planning and control

- Hijunka

- Inventory Management

Session 12 (Onsite Practical)

- Practical Simulation Session on Value Stream Mapping at Simulated Factory at Hotel Galadari Colombo

Session 10 (Exam & Project Review)

- Examination 2- MCQ Type online exam

- Review the project on 8 Step Problem Solving

Session 11 (Online)

- Value Stream Mapping (Deep)

- Pull System Kanban

- Production planning and control

- Hijunka

- Inventory Management

Session 12 (Onsite Practical)

- Practical Simulation Session on Value Stream Mapping at Simulated Factory at Hotel Galadari Colombo

Session 13 (Online)

- BIQ and M&I flow mapping

- Quality Support Metrix

- Error proofing & Self Ownership

- Human Value Stream

Session 14 (Onsite Practical)

- Practical Simulation Session on Built In Quality at Simulated Factory at Hotel Galadari Colombo

Session 15 (Onsite Practical)

- Practical Simulation Session on Hoshin Kanri at Simulated Factory at Hotel Galadari Colombo

Session 13 (Online)

- BIQ and M&I flow mapping

- Quality Support Metrix

- Error proofing & Self Ownership

- Human Value Stream

Session 14 (Onsite Practical)

- Practical Simulation Session on Built In Quality at Simulated Factory at Hotel Galadari Colombo

Session 15 (Onsite Practical)

- Practical Simulation Session on Hoshin Kanri at Simulated Factory at Hotel Galadari Colombo

Session 16 (Online)

- Lean Leadership

- Daily management ,Kamishibi & Jishuken

- Supplier Integration

- Chassis model and PCU

- AM & PM (Advanced)

Your Investment

US $ 990

* Postal / Courier charges will be separately billed for overseas participants

Session 16 (Online)

- Lean Leadership

- Daily management ,Kamishibi & Jishuken

- Supplier Integration

- Chassis model and PCU

- AM & PM (Advanced)

Your Investment

US $ 990

* Postal / Courier charges will be separately billed for overseas participants

Lean Leader Black Belt

Why?

If you are a Lean Black Belt holder, you will have the knowledge about the basis of Lean, 8 Types of Wastes, 5S for Productivity, Gemba etc. You will be able to learn more about Process Mapping, Lean Metrices, Lean Problem-solving Techniques.

If you need to gain the knowledge on areas such as Value Stream Mapping & Current & Future (Intro Level), Lean New Product Development, QCO, Chassis model and PCU, Lean Leadership, Daily management & Kamishibi, Jishuken, Supplier Integration, Chassis model and PCU, AM & PM, etc. the Lean Black Belt Program can help you with that. As a black belt holder, you can take the responsibility to coach Lean practitioners on process improvement methods and activities, and conduct training on Lean methodologies. These are just a few of the many reasons for why you should earn the Lean Black Belt.

World Class Content

Licensing

Scale and accelerate leadership development and lean concepts with our expertise, deliver you the best skill set that an industry professional should have. Enabling to lead their organization & the team to its goals.

Lean Leader Black Belt

Why?

If you are a Lean Black Belt holder, you will have the knowledge about the basis of Lean, 8 Types of Wastes, 5S for Productivity, Gemba etc. You will be able to learn more about Process Mapping, Lean Metrices, Lean Problem-solving Techniques.

If you need to gain the knowledge on areas such as Value Stream Mapping & Current & Future (Intro Level), Lean New Product Development, QCO, Chassis model and PCU, Lean Leadership, Daily management & Kamishibi, Jishuken, Supplier Integration, Chassis model and PCU, AM & PM, etc. the Lean Black Belt Program can help you with that. As a black belt holder, you can take the responsibility to coach Lean practitioners on process improvement methods and activities, and conduct training on Lean methodologies. These are just a few of the many reasons for why you should earn the Lean Black Belt.

World Class Content

Licensing

Scale and accelerate leadership development and lean concepts with our expertise, deliver you the best skill set that an industry professional should have. Enabling to lead their organization & the team to its goals.

Lean Leader Black Belt

Why?

If you are a Lean Black Belt holder, you will have the knowledge about the basis of Lean, 8 Types of Wastes, 5S for Productivity, Gemba etc. You will be able to learn more about Process Mapping, Lean Metrices, Lean Problem-solving Techniques.

If you need to gain the knowledge on areas such as Value Stream Mapping & Current & Future (Intro Level), Lean New Product Development, QCO, Chassis model and PCU, Lean Leadership, Daily management & Kamishibi, Jishuken, Supplier Integration, Chassis model and PCU, AM & PM, etc. the Lean Black Belt Program can help you with that. As a black belt holder, you can take the responsibility to coach Lean practitioners on process improvement methods and activities, and conduct training on Lean methodologies. These are just a few of the many reasons for why you should earn the Lean Black Belt.

World Class Content

Licensing

Scale and accelerate leadership development and lean concepts with our expertise, deliver you the best skill set that an industry professional should have. Enabling to lead their organization & the team to its goals.

Center for Lean Excellence is accredited from

ISO 18404 Certified Lean Belt Training Programs

Center for Lean Excellence is accredited from

ISO 18404 Certified Lean Belt Training Programs

Center for Lean Excellence is accredited from

ISO 18404 Certified Lean Belt Training Programs

Certification

- Al the students who meet the pass criteria of minimum 70% for the exam are eligible for the certification

- The students will receive the digital certification upon the successful completion of the course

- Printed dual certificates (Certified Lean Initiator and Certified Lean Black Belt) will be sent to the passed students via postal services by Center for Lean Excellence

Certification

- Al the students who meet the pass criteria of minimum 70% for the exam are eligible for the certification

- The students will receive the digital certification upon the successful completion of the course

- Printed dual certificates (Certified Lean Initiator and Certified Lean Black Belt) will be sent to the passed students via postal services by Center for Lean Excellence

Certification

- Al the students who meet the pass criteria of minimum 70% for the exam are eligible for the certification

- The students will receive the digital certification upon the successful completion of the course

- Printed dual certificates (Certified Lean Initiator and Certified Lean Black Belt) will be sent to the passed students via postal services by Center for Lean Excellence

Course Details

The most important subjects which will be covered are: Lean Action Workout, the 8 types of waste, client value, Value Stream Mapping, Flow, Pull, 5S, Error Proofing and Visual Management, Practically applicable knowledge.

Course Details

The most important subjects which will be covered are: Lean Action Workout, the 8 types of waste, client value, Value Stream Mapping, Flow, Pull, 5S, Error Proofing and Visual Management, Practically applicable knowledge.

Course Details

The most important subjects which will be covered are: Lean Action Workout, the 8 types of waste, client value, Value Stream Mapping, Flow, Pull, 5S, Error Proofing and Visual Management, Practically applicable knowledge.

Why chose our institute black belt?

- After the program you will be able to address challenges such as, supplier and RM issues, customer variations, productivity loss etc.

Globally recognized certificate from ICEES Global (an ISO 18404 Certified Company) - Your progress in reviewed and evaluated by Lean Experts at Center for Lean Excellence and marks will be awarded based on some set criteria.

- Training that is completely individualized based on an examination of both the existing situation and the goals of the implementation.

- After the program you will be able to address challenges such as, supplier and RM issues, customer variations, productivity loss etc.

Why chose our institute black belt?

- After the program you will be able to address challenges such as, supplier and RM issues, customer variations, productivity loss etc.

Globally recognized certificate from ICEES Global (an ISO 18404 Certified Company) - Your progress in reviewed and evaluated by Lean Experts at Center for Lean Excellence and marks will be awarded based on some set criteria.

- Training that is completely individualized based on an examination of both the existing situation and the goals of the implementation.

- After the program you will be able to address challenges such as, supplier and RM issues, customer variations, productivity loss etc.

Why chose our institute black belt?

- After the program you will be able to address challenges such as, supplier and RM issues, customer variations, productivity loss etc.

Globally recognized certificate from ICEES Global (an ISO 18404 Certified Company) - Your progress in reviewed and evaluated by Lean Experts at Center for Lean Excellence and marks will be awarded based on some set criteria.

- Training that is completely individualized based on an examination of both the existing situation and the goals of the implementation.

Best Institute for

Lean Leader Black Belt..!