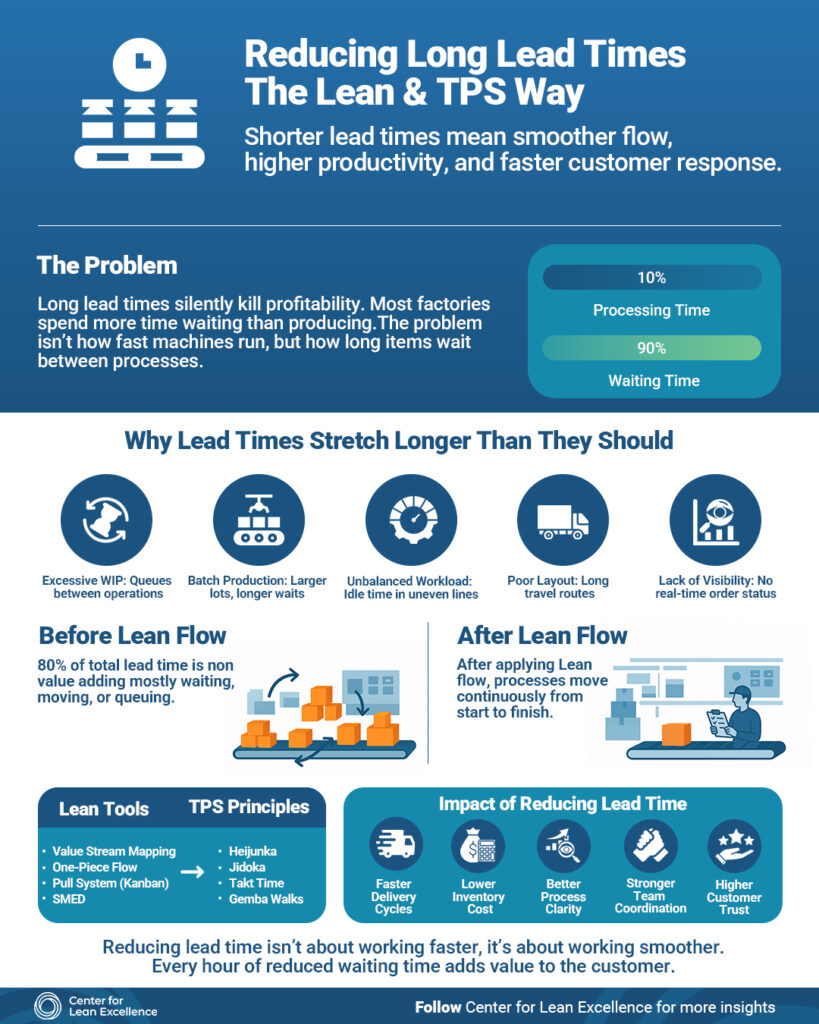

How ‘Reducing Lead Time’ Transforms Factory Performance? In modern manufacturing, speed is not just about machines running faster; it’s about how smoothly materials, information and decisions flow across the factory floor. ‘products don’t spend most of their time being worked on; they spend most of their time waiting.‘

Long lead times silently damage profitability, customer trust and operational stability. They stretch delivery commitments, hide inefficiencies, inflate inventory and make teams reactive instead of proactive. Understanding and reducing lead time is a foundational capability in Lean manufacturing and it’s at the heart of both Toyota Production System.

Why Lead Time Is the Hidden Cost Driver in Manufacturing

In many factories, machines are not the constraint; waiting time is. Material queues form between stations. Large batches stagnate. Operators walk long distances. Information flows late or gets lost. These delays accumulate, turning a few minutes of waiting into days or sometimes even weeks of lead time.

Manufacturers often discover that their actual processing time is only 5–10% of the total lead time. The remaining 90%? Pure waiting.

By learning the principles taught in TPS including flow, pull, takt, and standardization; companies gain the mindset to see and remove the causes of long lead time.

Common Reasons Lead Time Grows Longer Than It Should

Even high-performing factories unknowingly create delays. The main culprits include:

1. Excessive Work-in-Progress (WIP)

Large batches create big waiting queues and congest the shop floor.

2. Imbalance Between Operations

Some stations run faster, some slower—creating bottlenecks and inconsistent flow.

3. Inefficient Layout

Poorly arranged machines force operators and materials to travel long distances.

4. Lack of Real-Time Visibility

Without clear status tracking, orders wait longer simply because no one notices they’re stuck.

5. Slow Changeovers

Long setup times push teams to produce in batches instead of flow.

The Impact of Reducing Lead Time

Shorter lead time is not just about speed; it’s about stability, cost reduction and competitiveness.

When lead time drops, companies experience:

- Faster and more reliable deliveries

- Reduced inventory and lower carrying cost

- Better alignment between departments

- Visually clearer processes that highlight problems early

- Greater customer confidence and easier repeat business

Companies that apply TPS principles often see dramatic improvements in throughput, cash flow and quality; sometimes within weeks.

Lean and TPS Tools That Directly Reduce Lead Time

Value Stream Mapping (VSM)

A full-picture view of material and information flow to identify delays, waste and improvement points.

One-Piece Flow & Pull Systems

Smooth movement of materials, reducing batch delays and minimizing waiting.

Kanban

A visual system that controls production based on real customer demand preventing overproduction and excess WIP.

SMED (Quick Changeover)

Reducing setup time so teams can run smaller batches without losing productivity.

Heijunka (Level Loading)

Balancing production to prevent peaks, valleys, and bottlenecks.

Jidoka

Building quality into the process so defects don’t create delays downstream.

Takt Time

Aligning production speed with customer demand to create stable flow.

These tools are more than techniques; they are part of the broader Toyota Management System, which focuses on leadership, problem-solving, daily management and continuous improvement culture.

Why Leadership Matters: The Management Side of Lead Time Reduction

Many manufacturers implement tools without transforming management behaviors. Tools alone don’t reduce lead time; management systems do.

Through TMS & TPS Trainings, leaders learn how to:

- Build problem-solving habits

- Coach teams on flow and standard work

- Restore stability during disruptions

- Create visual management systems

- Sustain improvements across months and years

Reducing lead time becomes a company wide discipline; not a one time project.

Lead Time Is the Ultimate Indicator of Operational Health

When factories understand what truly creates delays, they can redesign processes for flow, visibility and speed. Manufacturers who internalize TPS principles build operations that are faster, more reliable, more profitable and far more adaptable to market changes. Whether through hands-on training, leadership development, or structured improvement projects, applying TPS thinking transforms the factory from the ground up.