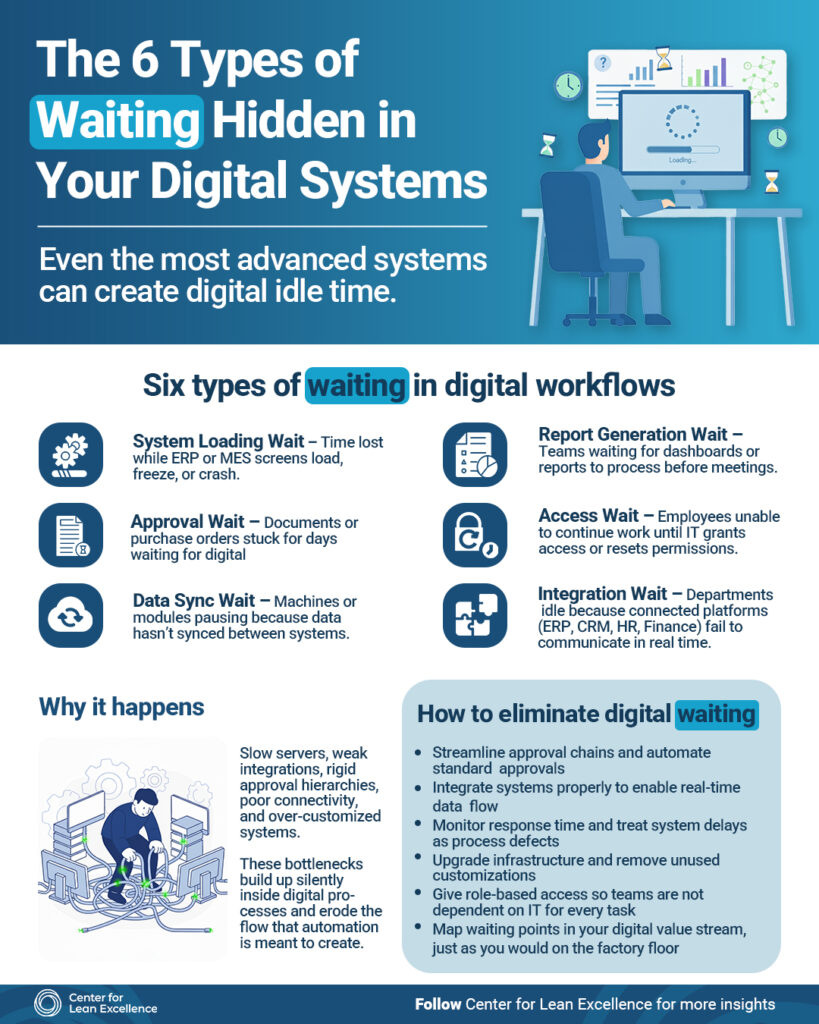

Hidden Waiting Time in Digital Systems: 6 Delays Slowing Your Workflow; Digital transformation promises faster, smarter operations, but hidden delays in digital systems; known as “digital waiting”, silently slow down organizations. This article uncovers six common types of waiting, explains why they happen and shows actionable ways to eliminate them.

1. System Loading Wait

System loading wait occurs when ERP, MES, or other digital tools take too long to load dashboards, reports, or screens.

Example: At a mid-sized automotive manufacturer, planners spent nearly 2 hours daily waiting for ERP reports to load. By upgrading their server and optimizing queries, they reduced wait time by 80%, improving daily order processing and decision-making speed.

How to fix it:

- Upgrade servers or database performance.

- Optimize system queries and workflows.

- Schedule heavy reports during off-peak hours.

Tip: Learn more about streamlining processes and eliminating delays with effective digital transformation solutions.

2. Approval Wait

Approval wait happens when digital processes require multiple approvals, causing bottlenecks.

Example: A procurement team waited 3 days for a purchase order approval because of a multi-level hierarchy in the ERP system. By automating routine approvals and setting delegation rules, the company cut approval delays by half.

How to fix it:

- Automate recurring approvals.

- Use conditional rules to bypass unnecessary levels.

- Monitor approval time metrics regularly.

3. Data Sync Wait

Data sync wait occurs when information between systems isn’t updated in real time, causing teams to pause work.

Example: Production managers couldn’t update schedules because inventory data from ERP hadn’t synced with MES. By implementing real-time integration tools, the delay was eliminated, and production planning improved.

How to fix it:

- Integrate systems for real-time data flow.

- Automate batch updates where possible.

- Monitor sync failures and errors.

4. Report Generation Wait

Teams often wait for dashboards or reports to refresh before making decisions.

Example: A supply chain team waited for end-of-day reports to finalize shipments. By consolidating dashboards and using scheduled data refreshes, the company reduced reporting delays by 50%.

How to fix it:

- Consolidate reports and dashboards.

- Automate report generation during off-peak hours.

- Use lightweight analytics for daily monitoring.

5. Access Wait

Access wait occurs when employees cannot proceed until IT grants permissions or resets passwords.

Example: A new project team was delayed 2 days because they couldn’t access critical ERP modules. By implementing role-based access control and self-service password tools, access delays were nearly eliminated.

How to fix it:

- Implement role-based access management.

- Provide self-service password reset options.

- Review and update access rights regularly.

Tip: To ensure all digital systems run smoothly, explore streamlining processes for effective digital transformation, this approach helps remove bottlenecks and boosts workflow efficiency.

6. Integration Wait

Integration wait happens when systems like ERP, CRM, and Finance don’t communicate efficiently, requiring manual reconciliation.

Example: Sales and finance teams spent hours reconciling orders manually because their systems were disconnected. By deploying middleware for automated integration, the delay disappeared, improving customer satisfaction and order accuracy.

How to fix it:

- Use integration platforms or middleware.

- Ensure APIs and connections are maintained.

- Regularly audit cross-system processes.

Why Hidden Digital Waiting Happens

Digital waiting often results from:

- Poor system integration

- Over-customized or outdated software

- Rigid approval structures

- Weak infrastructure

Even advanced systems create these delays if processes are not optimized. Lean thinking can identify and eliminate these wastes.

Measuring Hidden Waiting

- Track the time employees spend waiting on systems.

- Monitor bottlenecks in approvals, reports, or data syncs.

- Conduct monthly reviews and map digital processes like lean value streams.

Quick Wins to Reduce Digital Waiting Today

- Automate routine approvals – Reduce dependency on manual approvals.

- Integrate systems – Real-time data across ERP, MES, CRM.

- Optimize infrastructure – Remove bottlenecks and upgrade slow systems.

- Map delays – Identify waste like a lean expert.

- Educate employees – Encourage reporting of frequent delays.

Conclusion

Hidden digital waiting silently reduces efficiency and delays decisions. By identifying the six types of waiting and applying lean-inspired solutions, organizations can achieve faster workflows, higher productivity, and a truly connected digital environment.

Start mapping digital delays today, automate where possible, and monitor your systems; every minute saved compounds into measurable business value.