Discover the birthplace of the Toyota Production System (TPS) – where lean manufacturing was born and mastered. The Centre for Lean Excellence has partnered with Toyota to offer students a unique and invaluable opportunity to learn how lean management is applied inside the Toyota Factory.

Taking you behind the scenes at the Toyota car manufacturing plant, this Toyota factory tour is meant to teach people about the lean manufacturing industry and the rules people have come up with to succeed. By visiting these companies where lean management started, you will get a grasp of what can be done by following the rules of lean management. So why not bring you to where it all started – with a Toyota factory tour!

In this article, you will learn

| Topic | Key Insights |

| The Lean Leadership Role | Recognize how crucial lean leadership is to achieving lean success. |

| Success and Failure Modes | To steer clear of typical traps, learn from both achievements and failures. |

| Technical Lean Tools and Management | Learn the lean management techniques and tools that are necessary for success. |

| TPS as a Business Strategy | Discover how the Toyota Production System, or TPS, is a corporate strategy as well as an operational element. |

Why Toyota Factory Tours are Essential for Lean Leaders.

The Toyota Production System (TPS) began with Toyota. Toyota has been developing management principles for nearly 60 years, which form the basis of this lean manufacturing approach. This is backed by two main pillars: jidoka, which has the rough translation of “automation with human touch”

Just-In-Time elements.

Through employee creativity and eliminating waste, TPS provides good quality and reasonably priced products with fast delivery times. It is designed to allow both humans and machines to respond immediately when there is an interference in the production line and to ensure greater efficiency, smooth flow, and early resolution of issues. This is done by avoiding damage and delays to the production line.

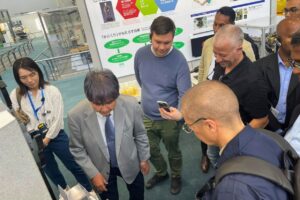

You will be able to see how Toyota’s TPS concept of jidoka and just in time is applied in their daily tasks to ensure the efficiency, quality and waste reduction and you will be learning from the world’s most efficient people such as Toshio Horikiri, Chairman of Toyota Engineering Corporation and Yasuhito Matsudaira, Senior Consultant at TMS & TPS Certificate Institute of Toyota Engineering Corp. This Toyota factory tour offers that exclusive access.

Key Lessons You’ll Learn on a Toyota Factory Tour

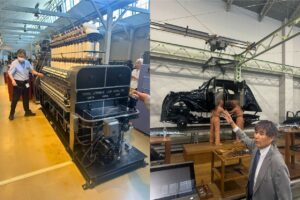

Unlike the free public plant tenures offered by Toyota, the Toyota factory tour stint will allow you to enter the bodyshop, assembly, and examination lines. It’ll also concentrate on the operation of the Toyota Production System, which is led by Toshio Horikiri, Chairman of Toyota Engineering Corporation.

The Toyota factory tour plant visits are guided with an emphasis on how the two pillars of Jidoka and Just-In-Time are applied in the day-to-day tasks of the Toyota company.

For illustration, “muda” in Japanese indicates “waste” or “inefficiency.” It’s employed to identify and exclude any inefficient practices or conduct that don’t contribute to increasing the quality of a product or service. From the design and accoutrements to the manufacturing process and final product delivery, it looks at every aspect of the product. Also, you’ll be able to interact directly with Muda during the Toyota factory tour.

Also, the Japanese term for “actual place,” gemba (現場), is generally used to describe the factory floor or any other location where work that creates value is done. It can also be spelled genba. According to some thinkers, it refers to the place where value is created. Japanese enterprises often add the related phrase “genchi gembutsu” (meaning “go and see”) to gemba, emphasizing the importance of firsthand observation and empiricism. These concepts come to life during a Toyota factory tour.

7 Things to Expect in a Toyota Factory Tour.

1. Presentation of the Toyota Production System (TPS)

Tour visitors should be able to see an in-depth presentation of the Toyota Production System (TPS) with a special emphasis on its two cornerstones:

- Just-In-Time

- Jidoka

2. Core Concepts Demonstrated on the Production Floor

The tour further delves into important concepts, including:

- The application of the 5S method

- Standard work

- Visual control

- Karakuri (electricity-free mechanical devices)

- Poka-yoke (mistake-proofing)

- Automated Guided Vehicles (AGVs)

- Kanban

These concepts are not merely illustrated in theory, but rather practised in action throughout the production floor of Toyota.

3. Jidoka in Action

A recurring theme throughout the tour is that of Jidoka, or “automation with a human touch.”

It speaks to the way in which humans and machine automation are combined.

Visitors get to witness firsthand the way in which, in operation, the machines and workers react when an abnormality—a mechanical defect, quality deficiency, or process slowdown—happens.

- Machines will automatically shut down

- Workers will pull a cord to correct the problem in an instant

It guarantees that defects are caught and fixed early, before faulty products move through and further down the line.

4. Quality and Efficiency Through Automation

Production incorporates more than just quality into every stage, in fact. Additionally, automating the detection and fixing of errors, instead of needing ongoing human watchfulness. This helps in:

- Saves costs

- Boosts efficiency

5. Manual First, Then Automate

As they make their way through the tour, guests will learn about the company’s philosophy of:

- Developing manual methods first

- Then automating

The assumption here is that:

- You have to be able to do a task manually and efficiently

- Find any anomalies

- And finally, automate

6. Tools for Optimizing Production

Kaizen (constant change for improvement), elimination of waste (muda), uneven workloads (mura), and overburden (muri) are all necessary tools for optimizing production.

Once the defects are found and understood, they are:

- Dealt with up-front in the tool design and process

- And production lines are the end result that are:

- Of high quality

- Cost-effective

- Flexible

- Simple to maintain

7. An Interactive Learning Experience

In fact, the Toyota factory tour is an interactive learning experience that illustrates how these philosophies are applied on the plant floor.

It gives invaluable insights into how consistently and reliably the company sustains operational excellence by:

- Exercising extreme attention to detail

- Creative problem-solving

- A people-oriented attitude

How a Toyota Factory Tour Boosts Your Lean Leadership Skills

Participating in our Toyota factory tour to study in Japan gives the student an experience that builds leaders and focuses on improving leadership skills. By partaking in this experience, students have the chance to get first-hand experience in the well-known Toyota Production System, also known as the TPS.

This experience will allow participants to observe lean principles at the place where it all started, at Toyota’s assembly plants and supplier facilities. Through hands-on experience and guided Toyota factory tours, attendees will understand basic principles of TPS.

This Toyota factory tour will explore the critical role of leadership in lean management practices, highlighting how Toyota’s leaders address problems and how continuous improvement is implemented. By engaging directly in the TPS system and participating in the reflective training sessions, leaders unconsciously develop the mindset and skills to drive their organization to success.

Why Choose the Center for Lean Excellence for Your Toyota Factory Tour

Center of Lean Excellence offers a once-in-a-blue-moon opportunity for most professionals aiming to gain more knowledge by partaking in an authentic and in-depth understanding of Toyota’s Production System. What sets our Toyota factory tour apart from others is the exclusive access to Toyota’s factories and suppliers in Japan. And also, this is guided by experts who are well seasoned in the TPS system and lean thinking.

Trainers who are certified by Toyota themselves provide attendees with rare insight into the lean principles and behaviors that most others don’t usually have an idea of—insights that made Toyota the global benchmark in operational excellence. This ability to obtain insider knowledge is unmatched for most leaders who are committed to mastering the concept of lean in their leadership. A Toyota factory tour gives access that no textbook can replicate.

To make sure that participants get the most out of their business trip to Japan, we include pre-tour and post-tour training. This helps the attendee build themselves a foundation for the next lecture beforehand and harden the learning curve with post-learn support by enabling the application of lean concepts—another strength of our Toyota factory tour experience.