TPS STUDY MISSION TO TOYOTA JAPAN

Exploring the Latest Knowledge in the Toyota Production System (TPS) with Toyota Engineering Corporation at the Source

Upcoming TPS Study Missions to Japan

Program Highlights

Focus Group

CEOs, MDs, Factory Owners, Consultants, Opex Leaders, Senior Managers

Toyota & Supplier Visits

Visit Toyota Motor Japan and its supplier plants to witness the TPS in action.

TPS Workshops

Two interactive workshops with hands-on simulations to master the essentials of the TPS

Explore Japan

Experience Japanese culture, cuisine, the Shinkansen, and iconic landmarks.

Visit Iternarary

Day 01 | Arrival & Orientation

- Arrive in Japan & Travel to the Hotel at Nagoya | Check in Time – 3.00 pm

- 5.30 pm – 9.30 pm : Orientation to Japanese Culture. Japanese Traditional Tea Ceremony & Dinner

Day 02 | Workshop on TPS

- 9.00 am – 5.00 pm : Hands-on Experience in TPS Basics and Kaizen Methodology

- 6.30 pm Onwards: Japanese Dinner & Networking

Day 03 | Workshop & Toyota Meuseam

- 9.00 am – 12.00 pm : Prelimenary Study of the Factory Tour

- 1.00 pm – 4.00 pm : Explore Toyota Meuseam with Matsudaira Sensei

- 6.30 pm Onwards: Japanese Dinner & Networking

Day 04 | Toyota Supplier Factory Visits

- 8.00 am – 12.00 pm : Factory Visit 1 – Mifune (Manufacturing parts for instrument panels, fuel tanks, and seats)

- 1.30 pm – 5.30 pm : Visit 2 – Toyotake (CAr seat cover manufacturer)

- 6.30 Onwards : Japanese Dinner & Networking

Day 05 | Toyota Supplier Factory Visits

- 8.00 am – 12.00 pm : Factory Visit 3 – Avex (Ultra-precision/high-accuracy cutting/grinding processing parts)

- 1.30 pm – 5.30 pm : Travel to Tokyo for Toyota Assembly Plant Visit Preparation

Day 06 | Toyota Assembly Plant

- 8.00 am – 12.00 pm : Factory tour to Toyota Assembly Plant

- 1.30 pm – 5.30 pm : Reflection & Certification Awarding Ceromony

Day 07 | Reflection & Sightseeing

- 9.00 am Onwards: Hansei Reflection Break (Participants to use the day for reflection and site seeing in Japan)

Day 08 | Departure

- Participants will depart to their respective countries. If you wish to extend your stay in Japan, please let us know..

Visit Highlights

Factory Tour to Toyota Assembly Plant

Witness how Toyota uses TPS concepts like Jidoka and Just-In-Time (JIT) in their daily operations. These principles are practically applied in the assembly environment to ensure efficiency, quality, and reduced waste.

Toyota Tier I Supplier Visit

During the visit, we explore Tier 1 factories like Somic and Toyotake to gain a deeper understanding of how TPS is implemented across Toyota’s supplier base.

Toyota Tier II Supplier Visits

An Impressive fully automated manufacturing facility with digital lean concepts in practice. It is a fantastic experience to walk through the process and understand the details and TPS practices at Gemba. Factories like Avex/ Mifune will be visited during the tour

Basic TPS and Kaizen Hands-on Workshop

We begin with a basic TPS and Kaizen workshop to help participants grasp the fundamentals, conducted by senior TPS senseis from Toyota Engineering Corporation.

Prelimenary Factory Study Session

A dedicated workshop is conducted to highlight key concepts participants will observe during the factory visits and how these practices relate to the overall TPS methodology. This session also provides an opportunity to ask questions and clarify observations directly with the sensei.

Explore Toyota Museam

The Toyota Museum visit showcases TPS principles through historical exhibits and interactive displays, highlighting their impact on manufacturing.

Expert Dinner Dialogues

Engage in insightful conversations with TPS experts over dinner, discussing real-world applications and advanced concepts in a relaxed setting.

Japanese Cultural Experience

Immerse yourself in Japanese culture with activities such as a traditional tea ceremony, providing a deep understanding of its customs and aesthetics.

Expand Your Network

Expand your network by connecting with TPS practitioners worldwide. Create lasting relationships with like-minded professionals.

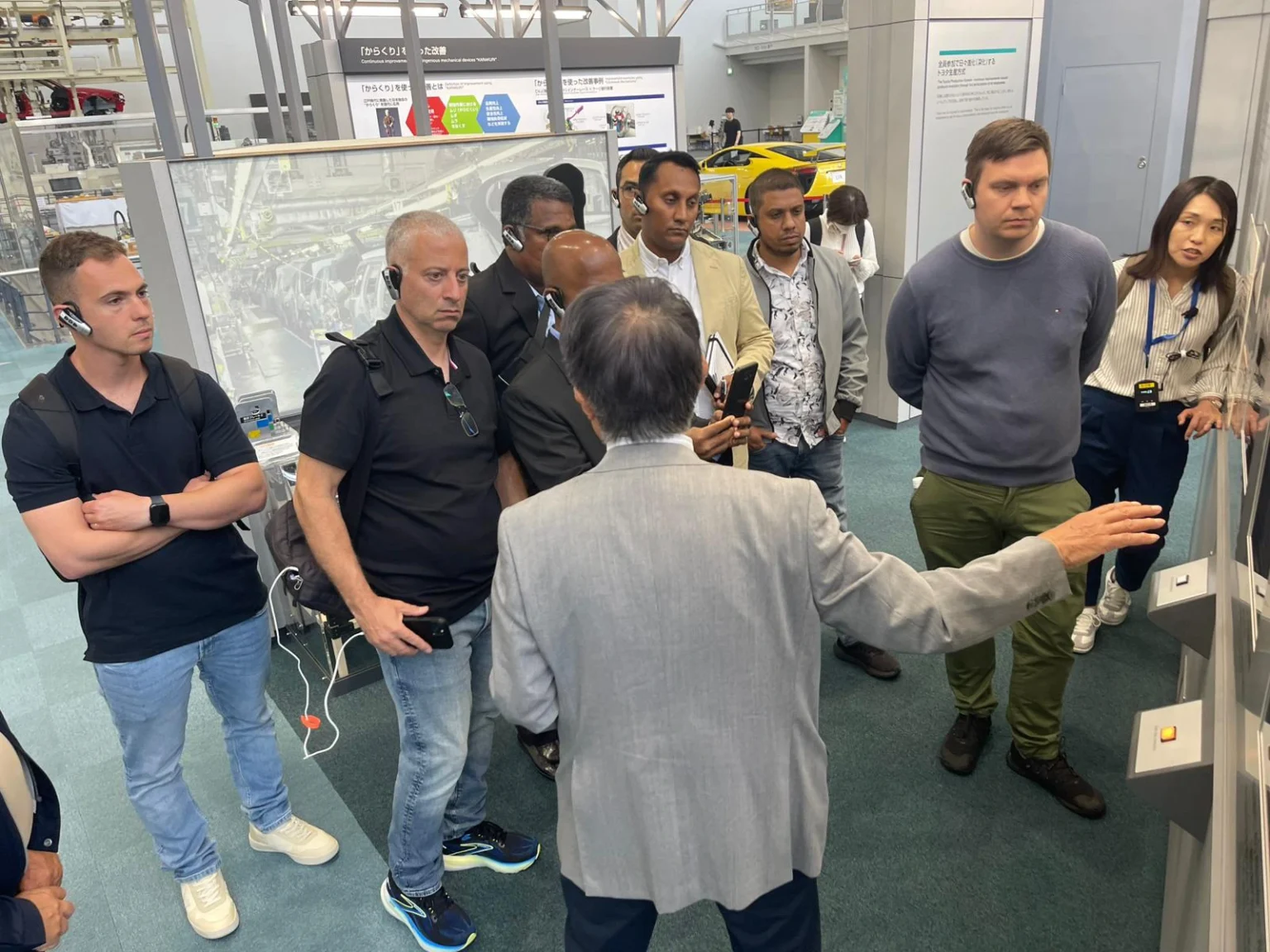

Previous Mission Visit Experience

Join Us

Create a memorable lasting experience, witness how TPS works in the real world, learn from the source, clarify your doubts, and make friends around the world.

Upcoming Missions 2026

Summer Mission – 21st to 28th June 2026: Register Now

Investment USD $4950

The above cost does NOT include airfare and visa-related expenses.

All related costs, including workshops, factory tours, 3-star single room hotel accommodation, variety of meal options, and tour related transportation charges, are included in the above price.

Special discount for TPS Grade IV , TMS Grade IV and TPS Grade III Certificate Holders

Call / Whatsapp Us +6586849818

Meet the August 2025 Study Mission Team

Our Previous Missions

Meet Your Senseis

Toshio Horikiri

Chairman of Toyota Engineering Corporation

Toshio Horikiri has had a distinguished career with Toyota. Since 2017, he has been the Chairman of Toyota Engineering Corporation and TMS TPS Certification Institute Japan.

Since 2008, he has also served as CEO of Toyota Management Institute in Nagoya, providing training on the Toyota Management System, and as Chief Director of TMS & TPS Certificate Institution.

His past roles include Chief Engineer for Overseas Production Support and China Project Division, General Manager at Kuozui Motors in Taiwan, and Assistant Manager in the Body Engineering Department, starting his career in 1966.

Yasuhito Matsudaira

Senior Consultant at TMS & TPS Certificate Institute of Toyota Engineering Corp. Worked in Toyota Motor Corp since 1979

After joining Toyota Motor Corp in 1979, Mr Matsudaira worked in the production technology and manufacturing division, starting as a technical expert in mechanical parts welding and integrated manufacturing processes in Japan.

Then he held positions as assistant director/ general manager in production preparation and technology development for resin parts, chassis parts, electronic parts, and final assembly lines.

He also served as a project leader in launching new vehicle plants in the United States and Canada. More recently, he worked as a representative vice president for Primearth EV Energy Co., a joint venture between Toyota Motor Corp and Panasonic that produces secondary batteries for vehicles.

In 2017, Mr Matsudaira became a senior consultant at Toyota Engineering Corp and Toyota Management Institute. Now he is using his expertise in TPS and TMS to serve many industries beyond the automotive sector.

Reserve Your Seat Now

Upon submission, our representative will contact you promptly. Rest assured, all information you provide is securely handled and strictly confidential, not shared with any third party.