Toyota Production System (TPS) Training Program

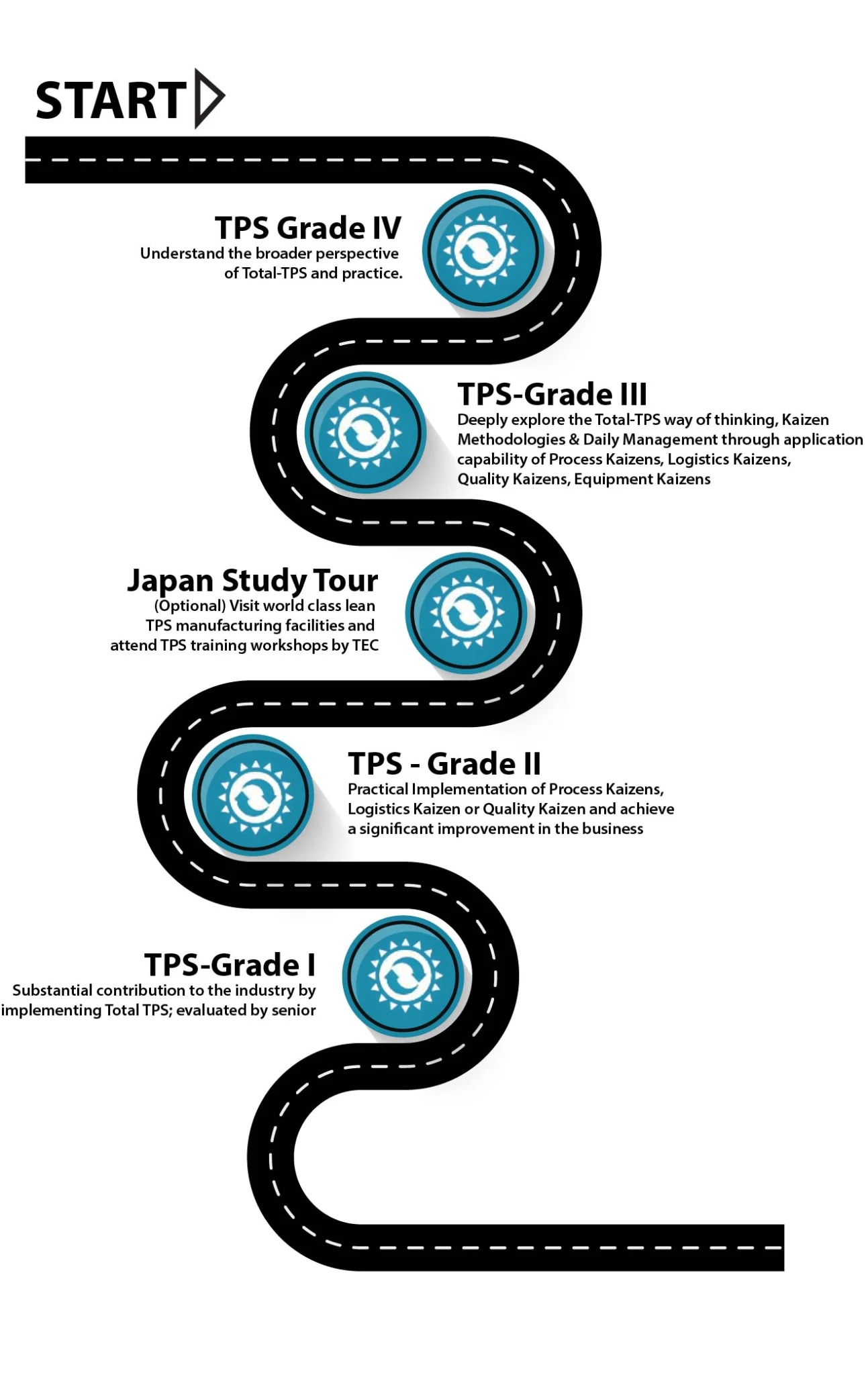

About Toyota Production System (TPS - Grade IV) Certificate Program

Toyota Production System (TPS) is considered as the world’s most successful strategy for operational excellence. This methodology was born, raised and evolved at Toyota Motor Corporation in Japan for seven decades and is now being used as a strategic weapon for businesses, governments, and institutes around the world.

TPS certification provides the most authentic, up to date, practical knowledge and application on Toyota Production System. TPS Level IV certification is an essential step for manufacturing leaders to develop “must-know” practical skills in Toyota Production System

BEST FOR

Leaders in the manufacturing sector

DELIVERY

100% Online | 24 Hours | 6 Saturdays

MATERIAL

TPS Text Book Delivered to Home

MODE

Instructor-led by Senior TPS Sensei

CERTIFICATE

Printed Certificate from TEC – Japan

About the Program Experience

1. What is the Toyota Production System (TPS) Grade IV Certification Program?

The TPS Grade IV Certification Program provides a solid foundation in the Toyota Production System. It introduces the essential TPS and Lean principles and guides participants on how to apply them effectively in real manufacturing settings. The program helps improve operational efficiency and supports the development of a strong culture of continuous improvement within organizations.

2. Who should enroll in this program?

Consulting and Improvement Professionals: Consultants, Lean Managers, TPM practitioners, continuous improvement leaders, and process improvement specialists who guide teams through operational excellence initiatives.

Manufacturing and Operations Teams: Production engineers, industrial engineers, plant leads, operations managers, and quality engineers who manage day to day factory performance.

Technical and Development Experts: Product development engineers and R and D professionals who want to strengthen their understanding of TPS principles to support design and innovation.

Business and Strategic Leaders: Business owners and CEOs who aim to elevate productivity, quality, and competitiveness through practical TPS Grade IV implementation.

3. Are there any prerequisites for enrollment?

There are no prerequisites for this program. Anyone who wants to learn Toyota Production System or Lean Management and apply them on the shop floor can join. The content covers essential theory along with practical application.

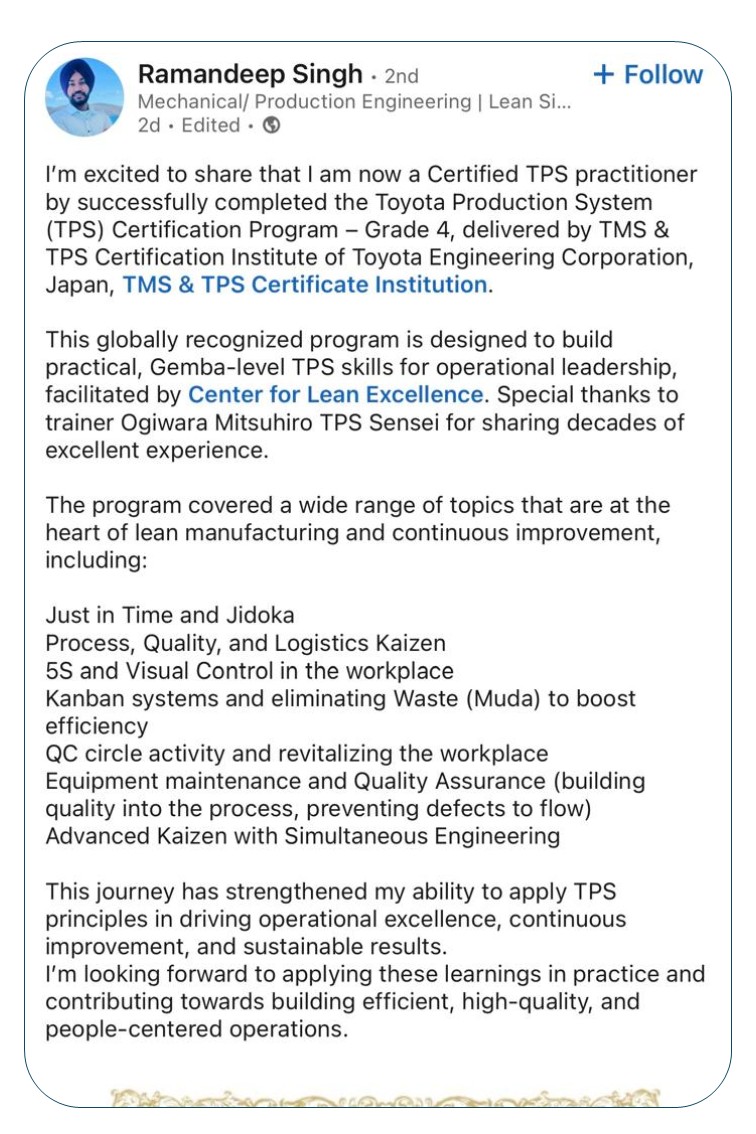

4. What topics are covered in the program?

Origins and Evolution of TPS

Understanding the history of Toyota, the spirit of the founders, and how TPS developed into Total TPS.Total TPS Framework

Learning the two pillars which are Just in Time and Jidoka, and how Total TPS operates as a complete manufacturing system.Workplace Revitalization and Standardization

Developing people, strengthening workplace discipline, applying 5S, visual control, and preparing standardized work documents.Operation Kaizen

Establishing standardized work, identifying MUDA, reallocating work, improving efficiency, and reducing lead time through practical kaizen.Logistics Kaizen

Improving part receiving, milk run systems, internal material flow, sequencing methods, and managing Kanban effectively.Equipment Kaizen

Applying autonomous and specialized maintenance, improving equipment reliability, and reducing setup time.Quality Kaizen

Building quality in process, preventing defects, strengthening quality assurance methods, and using visual checks and Poka Yoke.Advanced Kaizen for New Product Introduction

Using simultaneous engineering, production preparation, and Oobeya based management for smoother product launches.Company Strength Evaluation

Assessing organizational capability using TMS evaluation criteria to identify strengths and improvement areas.

5. What is the duration and format of the program?

This is a 100% online, instructor-led program, delivered by Toyota Senior Management. The program consists of 6 live interactive sessions, each 4 hours long, total 24 hours.

6. What are the benefits of obtaining the TPS Grade 4 Certification?

Globally recognized qualification

Receive a certification endorsed by Toyota Engineering Corporation and TMS TPS Certification Institute, respected across international manufacturing and consulting communities.Deep TPS mastery with practical improvement capability

Gain a strong understanding of Total TPS including Just in Time, Jidoka, standardized work, and all Kaizen streams together with the ability to identify MUDA, improve processes, and drive measurable results on the shop floor.Career advancement in manufacturing and consulting

Strengthen your professional profile as a Lean specialist, CI leader, engineer, manager, or consultant with proven TPS Grade IV credentials.Global professional networking

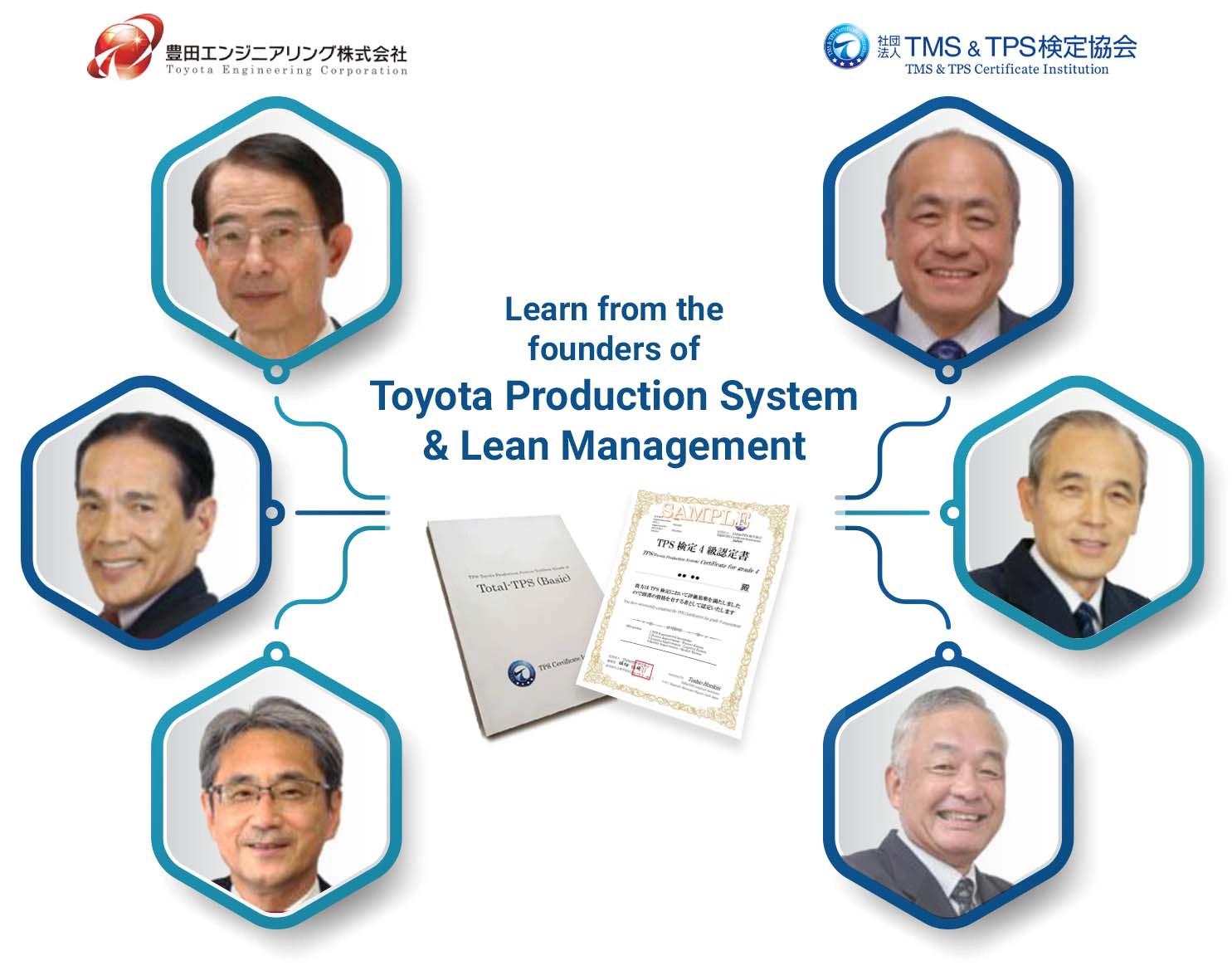

Connect with participants from many countries, share ideas, and build valuable international relationships for future collaboration.Direct guidance from Toyota experts

Learn directly from senior Toyota practitioners who bring decades of hands on TPS experience and real world insights.

7. What is the program fee, and how can I make payments?

Program Fee

The program fee is USD 895 per participant. DHL shipping charges for the study materials and the certificate will be added separately.

Shipping of Study Materials and Certificate

Study materials are couriered before the program begins once you complete your registration. The certificate is sent after you successfully complete the examination.

DHL Shipping Charges

India and Bangladesh USD 60

Asia and Middle East USD 80

Europe and Africa, USA, Canada and Australia USD 90

South America USD 120

Mexico USD 150

Payment Methods

You can make the payment through direct bank transfer or by using a credit or debit card.

8. Is there a certification exam at the end of the program and will I receive a certificate?

Yes. Participants must complete an examination(1-hour), consisting of MCQ questions, to qualify for the certification.

Upon passing the exam, you will receive a certificate from TMS and TPS Certification Institution, Japan.

9. How can I register for the program?

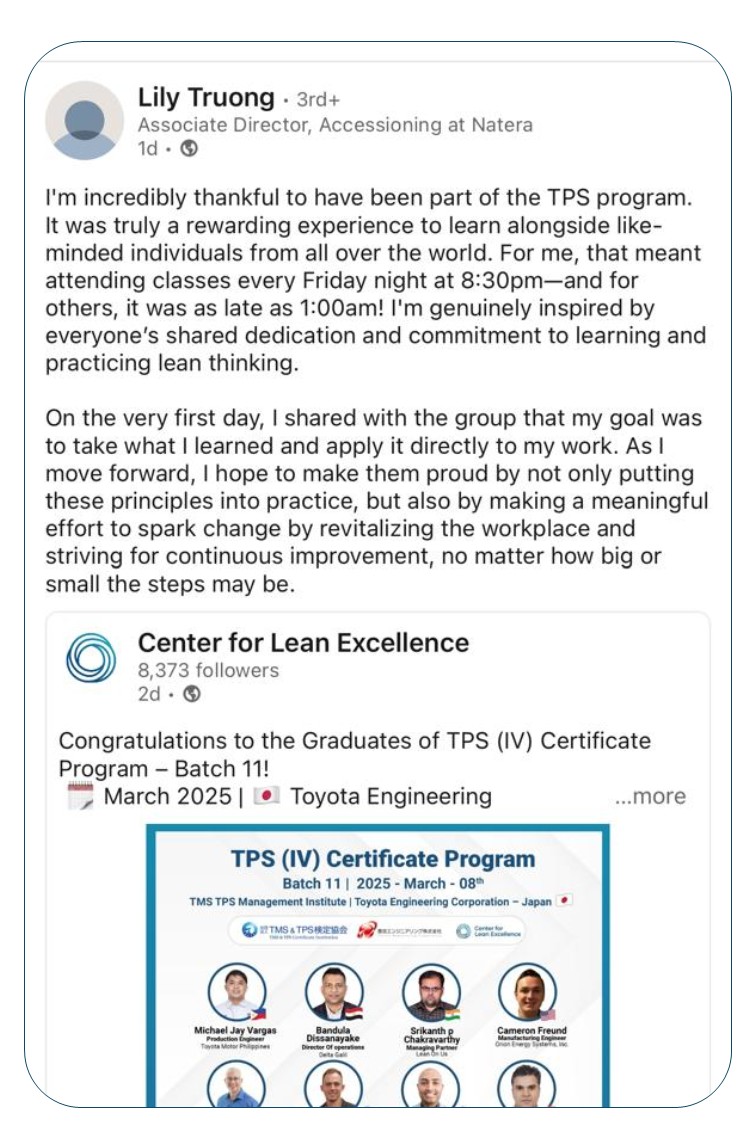

Congratulations to the "Batch 12" participants on their successful completion

Upcoming Programs 2026

March 2026 - Batch 14

- Introduction – 28th March 2026

- Session 01 – 4th April 2026

- Session 02 – 11th April 2026

- Session 03 – 18th April 2026

- Session 04 – 25th April

- Session 05 – 16th May 2026

- Examination – 30th May 2026

12.30 PM - 4.30 PM (Japan Time)

Program Schedule: 6 Saturdays

Exam: Online - 60 Mins

Transform Yourself Today!

Investment

USD 895.00

- Early bird discounts for registrations 1 month before the start date

- DHL charges for Textbook & Certificate will be separately billed

Contact us for more details:

Linkedin Notes Shared by Our Alumni

TPS Grade IV Program Content Plan

- Introduction and Warm up Session

- Getting to know about TPS Program and it’s struture

- Explanation of TPS Vocabulary

- Things to know about the TPS session and the final examination

- Introduction to Toyota Production System (Lean Management), Just In Time & Jidoka

- The background of lean management and TPS

- Sharing value within the company

- Introduction to pull production

- The concept of JIDOKA

- Big lot production & Small lot production

- Q&A

- Implantation of Total TPS

- Revitalizing workplace

- i. QC circle activity

ii. Multiskilled development (job rotation)

iii. Creative idea suggestion system

iv. Safety and health in workplace

v. Equipment maintenance

vi. Product quality

vii. Production division council

viii. Roles of supervisors

ix. Human resources development

x. Enhancement of welfare facility

- i. QC circle activity

- Participation and improvement of workplace

- 5S (4S and 1S) in workplace

- Visual control in the workplace

- Preparation of operation standards

- Operation Kaizen

- Establishment of standardized work

- Elimination of MUDA

- Reallocation of work

- Productivity (Work efficiency)

- Actual kaizen in process (lead-time reduction)

- Logistic Kaizen

- Part receiving

- Material handling in plant

- Kanban system

- Q&A

- Equipment Kaizen

- 5S of equipment

- Equipment maintenance

- Quality Kaizen

- Quality built in process

- Development of quality assurance mechanism

- QC network

- Quality assurance in process

- Quality assurance in purchasing parts

- Advanced Kaizen (New Product Introduction)

- SE (Simultaneous Engineering Activity)

- Production Preparation activity

- Manufacturing preparation

- Quality assurance in preparation activity

- Promotion of advanced kaizen by Oobeya system

- Evaluation of company strength and TMS

- Q&A

- TPS Grade IV Examination (80 MCQs | 60 Mins)

Meet Your Sensei

Ogiwara Mitsuhiro

Former Senior Manager with 37 Years of experience at Toyota Motor Corporation

-

2016 - 2019: Toyota Motor Corporation, Toyota, Japan

Administration Division, Plant Supporting Section, Motomachi Plant -

2011 - 2015: Production Manager, Sichuan Toyota Motor Co., Ltd. (China):

Supervising manufacturing, production control and logistics -

2008 - 2010: Assistant Project Section Manager

Global Production Center -

2005 - 2008: Plant Manager

GAC Toyota Motor Co., Ltd.(China) Supervising production, quality control and manufacturing -

2003 - 2004: Chief Expert : Global Production Center

Engaged in supporting the launch of a joint venture project with Guangzhou Automobile Group in China

-

1999 - 2002: Chief Expert Administration Division, Motomachi Plant

Engaged in supporting the launch of a joint venture project with Tianjin Automobile Industry Group in China -

1995 - 1999: Chief Leader

Chassis Manufacturing Division, Honsha Plant -

1991 - 1995: Production Engineering Division Ⅲ

Engaged in planning assembly process and promoting projects -

1978 - 1991: Final Assembly Department, Honsha Plant

Engaged in controlling assembly line work as a member of Engineering Service Division

All registered participants will receive the official Total TPS Grade IV textbook by courier. This book serves as the primary reference throughout the program and includes detailed explanations of every concept covered in the sessions. It provides clear illustrations, practical examples, and comprehensive content to support both learning and application on the shop floor.

Prestigious Certificate from Toyota Engineering Corporation

Previous Batches of Certified TPS Practitioners

“Participating in this program helped me to get a deeper understanding of the Total Toyota Production System. Revitalization of the workplace and respect for people are two key takeaways for me. I started involving the people in my workplace in daily problem solving and was amazed at the number of kaizens that can be done on the shop floor. It was an honor to learn from Masters and the Toyota Engineering Corporation.”